| |

Case

Study II: Control of a Chemical Reactor |

| |

| Author |

| |

Carla

Martín-Villalba |

| |

Departamento

de Informática y Automática, UNED |

| |

Juan del Rosal

16, 28040 Madrid, Spain |

|

|

|

| |

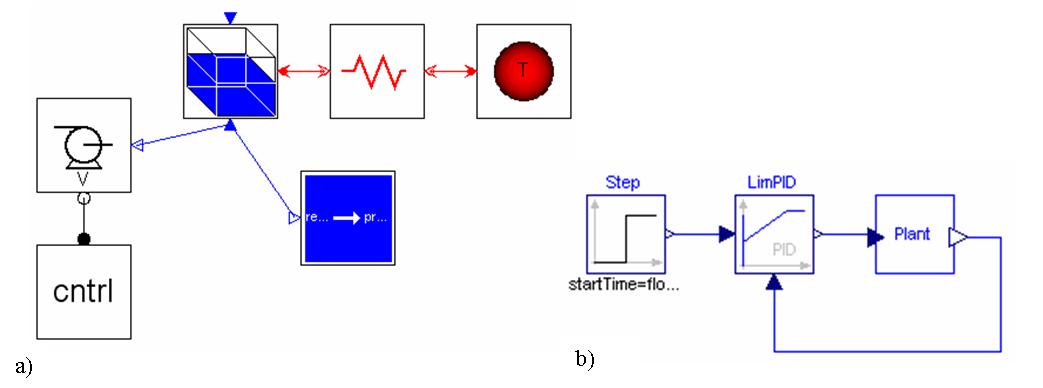

| The model of a batch

chemical reactor has been composed using JARA

Modelica library. The diagram of the reactor model is shown in Figure 1a

(it has been represented using Dymola). |

| |

| An exothermic reaction

A -> P is carried out in the liquid phase. The reactor contains a heat

exchanger, which can be operated with steam and with cooling water. The

diagram of the Modelica model describing the controlled system is shown

in Figure 1b. The PID controller model is included in the standard

Modelica library and it is designed according to the model provided

in (Astrom and Hagglund 95). It has limited output, anti-windup compensation

and setpoint weightings. It has the following parameters: proportional gain

(Kp), integral time constant (Ti), derivative time constant (Td), setpoint

weight for the proportional term (wp), setpoint weight for the derivative

term (wd), anti wind-up compensator constant (Ni), derivative filter parameter

(Nd), lower limit for the output (ymin) and upper limit for the output (ymax). |

| |

| |

Figure

1: Diagram of the reactor Modelica model: a) open-loop system;

and b) closed-loop system. |

| |

| The reactor's operation

policy is the following (Froment and Bischoff 79): |

| 1. |

Fill

up the reactor with the reacting liquid (the inflow is controlled

by a PID). |

| 2. |

Preheat to certain

temperature (T1), and let the reaction proceed adiabatically. |

| 3. |

Start cooling

when either the maximum allowable reaction temperature (Tmax) occurs

or the desired conversion is reached (xd), and cool down to the desired

temperature (Td). |

| 4. |

Empty the reactor. |

|

| |

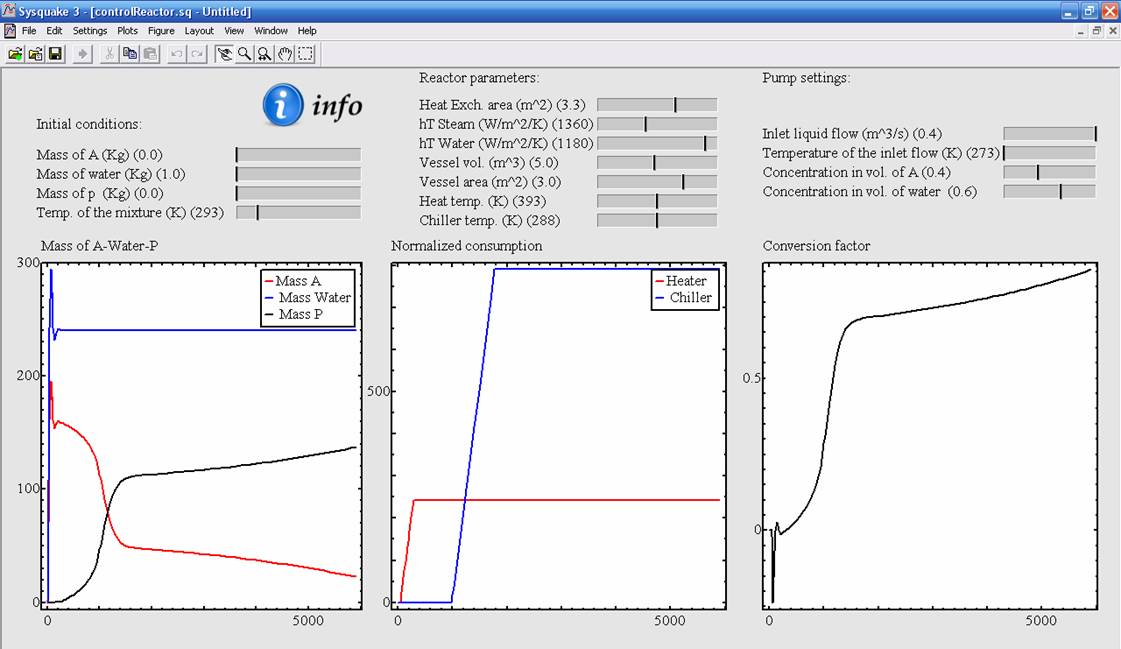

| The virtual-lab view

is shown in Figure 2. It contains sliders to change the model parameters,

the initial value of the state variables and the input variables. The "Settings"

menu allows the user to (see Figure 2): |

| 1. |

Change

the parameters of the control policy (i.e., T1, Tmax, xd, Td, and

the PID parameters). |

| 2. |

Set the communication

interval and the total simulation time. |

| 3. |

Launch a simulation

run. |

|

| In addition, the view

contains plots displaying the time evolution of some process variables,

including the mass of A, P and water, the mixture temperature and the pump

throughput. |

| |

|

Figure

2: View of the chemical reactor virtual-lab. |

| |

| References |

| Astrom, K. J. and

T. Hagglund (1995): "PID Controllers: Theory, Design and Tuning",

ISA Press. |

| Froment, G. F. and

K. B. Bischoff (1979): "Chemical Reactor Analysis and Design",

John Wiley & Sons, New York, USA. |

| |

|

| Carla Martin-Villalba |

| Last update: July

2007 |

| euclides

web server - Dept. Informatica y Automatica, UNED, Juan del Rosal 16,

28040 Madrid, Spain |