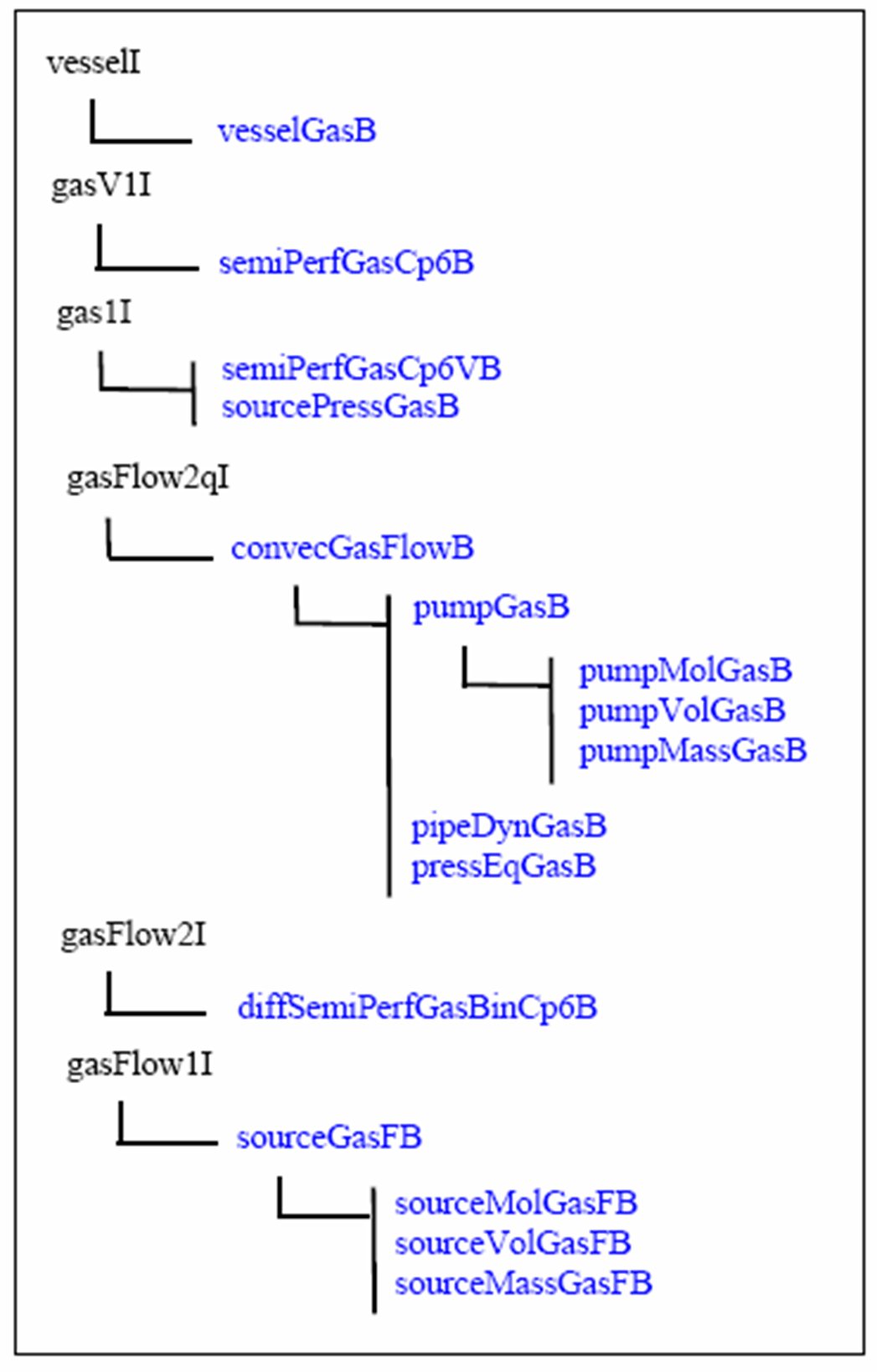

This package contains some models of gaseous CVs, gaseous mixtures TP (e.g., gas-flow by convection and diffusion, valves, pumps, etc.) and boundary conditions (i.e., gas-flow and pressure sources).

The mixtures of gases are considered ideal and they can be composed of an arbitrary number of components.

.

| Name | Description |

|---|---|

| Partial model - Convective flow of gas. | |

| Diffusion of an ideal, binary gas | |

| Gas flowing through a pipe | |

| Gas flowing through a pipe | |

| Partial model - Gas pump | |

| Gas pump. Setpoint: total mass-flow | |

| Gas pump. Setpoint: total molar-flow | |

| Gas pump. Setpoint: total volumetric-flow | |

| Homogeneous mixture of semi-perfect gases. | |

| Homogeneous mixture of semi-perfect gases inside a vessel. | |

| Gas-flow source | |

| Gas-flow source. Setpoint: total mass-flow, flow molar-fraction and flow temperature. | |

| Gas-flow source. Setpoint: total molar-flow, flow molar-fraction and flow temperature. | |

| Partial model - Pressure source. The across variables should be a funcion of time and state variables. | |

| Gas-flow source. Setpoint: total volume-flow, flow molar-fraction and flow temperature | |

| Vessel with a constant volume. |

JARA2i.gas.convecGasFlowB

JARA2i.gas.convecGasFlowB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

| cutHeatFC | inHeat | Heat flow - Connector F-C. Connector for the heat convection. |

partial model convecGasFlowB

"Partial model - Convective flow of gas."

extends interf.gasFlow2qI;

parameter Real CpCoefN[nComp,7] "Coefficients of the molar heat capacity at constant pressure

CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6";

parameter Real eps( unit="") = 1.E-10

"Small constant to avoid by-zero division";

parameter Real molEnthalpyRef[nComp]( unit="M.L2.t-2.mol-1") = zeros(nComp)

"Molar enthalpy of the components at the reference temperature";

parameter Real tempRef( unit="T") = 298

"Reference temperature for enthalpy";

Real totalMolF( unit="mol.t-1") "Total molar flow";

Boolean flowIsPosit( start=true) "Flow direction";

Real totalMolI( unit="mol") "Total number of mols";

Real totalMolO( unit="mol") "Total number of mols";

Real molEnthalpy[nComp]( unit="M.L2.t-2.mol-1")

"Molar enthalpy of the components";

equation

// Relationship among the interface variables

outMol.energyGF + inMol.energyGF + inHeat.heatF = 0;

inMol.molGF = - outMol.molGF;

inMol.molGF = inHeat.matterF;

// Flow direction

flowIsPosit = totalMolF > 0;

// Flow molar-fraction

if nComp > 1 then

for i in 1:(nComp-1) loop

inHeat.matterF[i] = if flowIsPosit then

totalMolF * inMol.molG[i] / ( totalMolI + eps) else

totalMolF * outMol.molG[i] / ( totalMolO + eps);

end for;

end if;

// Flujo molar total

totalMolF = sum(inHeat.matterF[i] for i in 1:nComp);

// Mols

totalMolI = sum(inMol.molG[i] for i in 1:nComp);

totalMolO = sum(outMol.molG[i] for i in 1:nComp);

// Flow temperature

inHeat.tempF = if flowIsPosit then inMol.tempG else outMol.tempG;

// Relationship between the molar enthalpy of the components and the temperature

for i in 1:nComp loop

molEnthalpy[i] = molEnthalpyRef[i] +

CpCoefN[i,1] * ( inHeat.tempF - tempRef) +

CpCoefN[i,2] * 1/2 * ( inHeat.tempF^ 2 - tempRef^ 2) +

CpCoefN[i,3] * 1/3 * ( inHeat.tempF^ 3 - tempRef^ 3) +

CpCoefN[i,4] * 1/4 * ( inHeat.tempF^ 4 - tempRef^ 4) +

CpCoefN[i,5] * 1/5 * ( inHeat.tempF^ 5 - tempRef^ 5) +

CpCoefN[i,6] * 1/6 * ( inHeat.tempF^ 6 - tempRef^ 6) +

CpCoefN[i,7] * 1/7 * ( inHeat.tempF^ 7 - tempRef^ 7);

end for;

// Total flow of energy

sum(inHeat.matterF[i]*molEnthalpy[i] for i in 1:nComp) = if flowIsPosit then inMol.energyGF else -outMol.energyGF;

end convecGasFlowB;

JARA2i.gas.diffSemiPerfGasBinCp6B

JARA2i.gas.diffSemiPerfGasBinCp6B

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | molEnthalpyRef[2] | 0 | Molar enthalpy at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature [T] |

| Real | CpCoefN[2, 7] | Coefficients of the molar heat capacity at constant pressure Cp[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | diffLength | Distance between the control volumes [L] | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | perfGasConst | Constant of the perfect gases [M.L2.t-2.T-1] |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive |

| cutGasR | outMol | Gas flow - Connector Resistive |

model diffSemiPerfGasBinCp6B "Diffusion of an ideal, binary gas"

extends interf.gasFlow2I(nComp=2);

parameter Real molEnthalpyRef[ 2]( unit="M.L2.t-2.mol-1") = 0

"Molar enthalpy at the reference temperature";

parameter Real tempRef( unit="T") = 298

"Reference temperature";

parameter Real CpCoefN[ 2,7] "Coefficients of the molar heat capacity at constant pressure

Cp[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6";

parameter Real diffLength( unit="L")

"Distance between the control volumes";

parameter Real eps( unit="") = 1.E-10

"Small constant to avoid by-zero division";

parameter Real perfGasConst( unit="M.L2.t-2.T-1")

"Constant of the perfect gases";

protected

Real diffArea( unit="L2")

"Diffusion section between the control volumes";

Real diffCoefI( unit="L2.t-1") "Diffusion coefficient";

Real diffCoefO( unit="L2.t-1") "Diffusion coefficient";

Real gasIVolume( unit="L3") "Volume of the gas mixture";

Real gasOVolume( unit="L3") "Volume of the gas mixture";

Real molEnthalpyTempI[ 2]( unit="M.L2.t-2.mol-1")

"Molar enthalpy of the flow from inMass to outMass";

Real molEnthalpyTempO[ 2]( unit="M.L2.t-2.mol-1")

"Molar enthalpy of the flow from outMass to inMass";

equation

// Relationship among the interface variables

inMol.molGF = - outMol.molGF;

inMol.energyGF + outMol.energyGF = 0;

// State equation of the perfect gases

( inMol.pressG + eps) * gasIVolume = (inMol.molG[1] + inMol.molG[2]) * perfGasConst * inMol.tempG;

( outMol.pressG + eps) * gasOVolume = (outMol.molG[1] + outMol.molG[2]) * perfGasConst * outMol.tempG;

// Fick law

inMol.molGF = diffArea * ( diffCoefI * inMol.molG / ( gasIVolume + eps) -

diffCoefO * outMol.molG / ( gasOVolume + eps)) / diffLength;

// Molar-enthalpy flow from inMass to outMass

molEnthalpyTempI = molEnthalpyRef + CpCoefN * [ inMol.tempG - tempRef;

1/2 * ( inMol.tempG^ 2 - tempRef^ 2);

1/3 * ( inMol.tempG^ 3 - tempRef^ 3);

1/4 * ( inMol.tempG^ 4 - tempRef^ 4);

1/5 * ( inMol.tempG^ 5 - tempRef^ 5);

1/6 * ( inMol.tempG^ 6 - tempRef^ 6);

1/7 * ( inMol.tempG^ 7 - tempRef^ 7)];

// Molar-enthalpy flow from outMass to inMass

molEnthalpyTempO = molEnthalpyRef + CpCoefN * [ outMol.tempG - tempRef;

1/2 * ( outMol.tempG^ 2 - tempRef^ 2);

1/3 * ( outMol.tempG^ 3 - tempRef^ 3);

1/4 * ( outMol.tempG^ 4 - tempRef^ 4);

1/5 * ( outMol.tempG^ 5 - tempRef^ 5);

1/6 * ( outMol.tempG^ 6 - tempRef^ 6);

1/7 * ( outMol.tempG^ 7 - tempRef^ 7)];

// Enthalpy flow

inMol.energyGF = diffArea * ( diffCoefI * sum(inMol.molG[i]*molEnthalpyTempI[i] for i in 1:2) /

( gasIVolume + eps) -

diffCoefO * sum(outMol.molG[i]* molEnthalpyTempO[i] for i in 1:2) /

( gasOVolume + eps)) / diffLength;

end diffSemiPerfGasBinCp6B;

JARA2i.gas.pipeDynGasB

JARA2i.gas.pipeDynGasB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Real | length | Pipe length [L] | |

| Real | section | Pipe cross-section [L2] | |

| Real | wettedArea | Wetted area of the pipe [L2] | |

| Real | perfGasConst | Constant of the perfect gases [M.L2.t-2.T-1] | |

| Real | molecWeigth[nComp] | Molecular weight of the components [M.mol-1] | |

| Real | epsMomentum | 1 | Dynamic balance of linear momentum. = small value. Steady-state balance. |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

| cutHeatFC | inHeat | Heat flow - Connector F-C. Connector for the heat convection. |

| cutReceiver | setPointSignal | Setpoint signal |

model pipeDynGasB "Gas flowing through a pipe"

extends convecGasFlowB;

cutsB.cutReceiver setPointSignal( dim=1, signal={valveOpeningSP})

"Setpoint signal";

Real valveOpeningSP( unit="") "Setpoint of the valve opening";

parameter Real length( unit="L") "Pipe length";

parameter Real section( unit="L2") "Pipe cross-section";

parameter Real wettedArea( unit="L2") "Wetted area of the pipe";

parameter Real perfGasConst( unit="M.L2.t-2.T-1")

"Constant of the perfect gases";

parameter Real molecWeigth[nComp]( unit="M.mol-1")

"Molecular weight of the components";

parameter Real epsMomentum( unit="") = 1 "Dynamic balance of linear momentum.

= small value. Steady-state balance.";

protected

Real veloc( unit="L.t-1") "Velocity of the flow";

Real linMomentum( unit="M.L.t-1") "Lineal momentum";

Real pressForce( unit="M.L.t-2") "Pressure-diference force";

Real fricForce( unit="M.L.t-2") "Friction force";

Real gasDensity( unit="M.L-3") "Gas density";

Real fanning( unit="") "Fanning's adimensional coeficient";

Real totalMassF( unit="M.t-1") "Total mass-flow";

Real totalForce( unit="M.L.t-2") "Total force";

Real valveOpening( unit="", min=0, max=1) "Valve opening. Bounded value";

equation

// Density of the gas flow

gasDensity = if linMomentum > 0 then

sum(molecWeigth[i]*inMol.molG[i] for i in 1:nComp) * inMol.pressG /

( totalMolI * perfGasConst * inMol.tempG + eps) else

sum(molecWeigth[i]*outMol.molG[i] for i in 1:nComp) * outMol.pressG /

( totalMolO * perfGasConst * outMol.tempG + eps);

// Pressure-difference force

pressForce = section * ( inMol.pressG - outMol.pressG);

// Friction force

fricForce = if linMomentum > 0 then

-wettedArea * 0.5 * gasDensity * veloc^ 2 * fanning else

wettedArea * 0.5 * gasDensity * veloc^ 2 * fanning;

// Bounding of the valve-opening signal

valveOpening = if valveOpeningSP > 1 then

1 else

if valveOpeningSP < 0 then

0 else

valveOpeningSP;

// Linear momentum balance

totalForce = fricForce + valveOpening^ 2 * pressForce;

epsMomentum * der(linMomentum) = totalForce;

when linMomentum > 0 and not ( sum(inMol.molG[i] for i in 1:nComp) > 0) or

linMomentum < 0 and not ( sum(outMol.molG[i] for i in 1:nComp) > 0) or

not valveOpeningSP > 0 then

reinit(linMomentum,0);

end when;

linMomentum = totalMassF * length;

totalMassF = sum(molecWeigth[i]*inHeat.matterF[i] for i in 1:nComp);

totalMassF = section * ( gasDensity + eps) * veloc;

end pipeDynGasB;

JARA2i.gas.pressEqGasB

JARA2i.gas.pressEqGasB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Real | Kprop | 1E3 | Coefficient [mol.t.L.M-1] |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

| cutHeatFC | inHeat | Heat flow - Connector F-C. Connector for the heat convection. |

model pressEqGasB "Gas flowing through a pipe" extends convecGasFlowB; parameter Real Kprop( unit="mol.t.L.M-1") = 1E3 "Coefficient"; protected Real pressDif( unit="M.L-1.t-2") "Pressure difference"; Real relatError( unit="") "Relative error"; equation // Pressure difference // It has been arbitrary defined that the molar flow is proportional to the pressure gradient. pressDif = inMol.pressG - outMol.pressG; // The molar flow is proportional to the pressure difference totalMolF = Kprop * pressDif; // Relative error of assuming zero pressure-difference relatError = abs(pressDif) / ( 0.5 * ( inMol.pressG + outMol.pressG + eps)); end pressEqGasB;

JARA2i.gas.pumpGasB

JARA2i.gas.pumpGasB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

| cutHeatFC | inHeat | Heat flow - Connector F-C. Connector for the heat convection. |

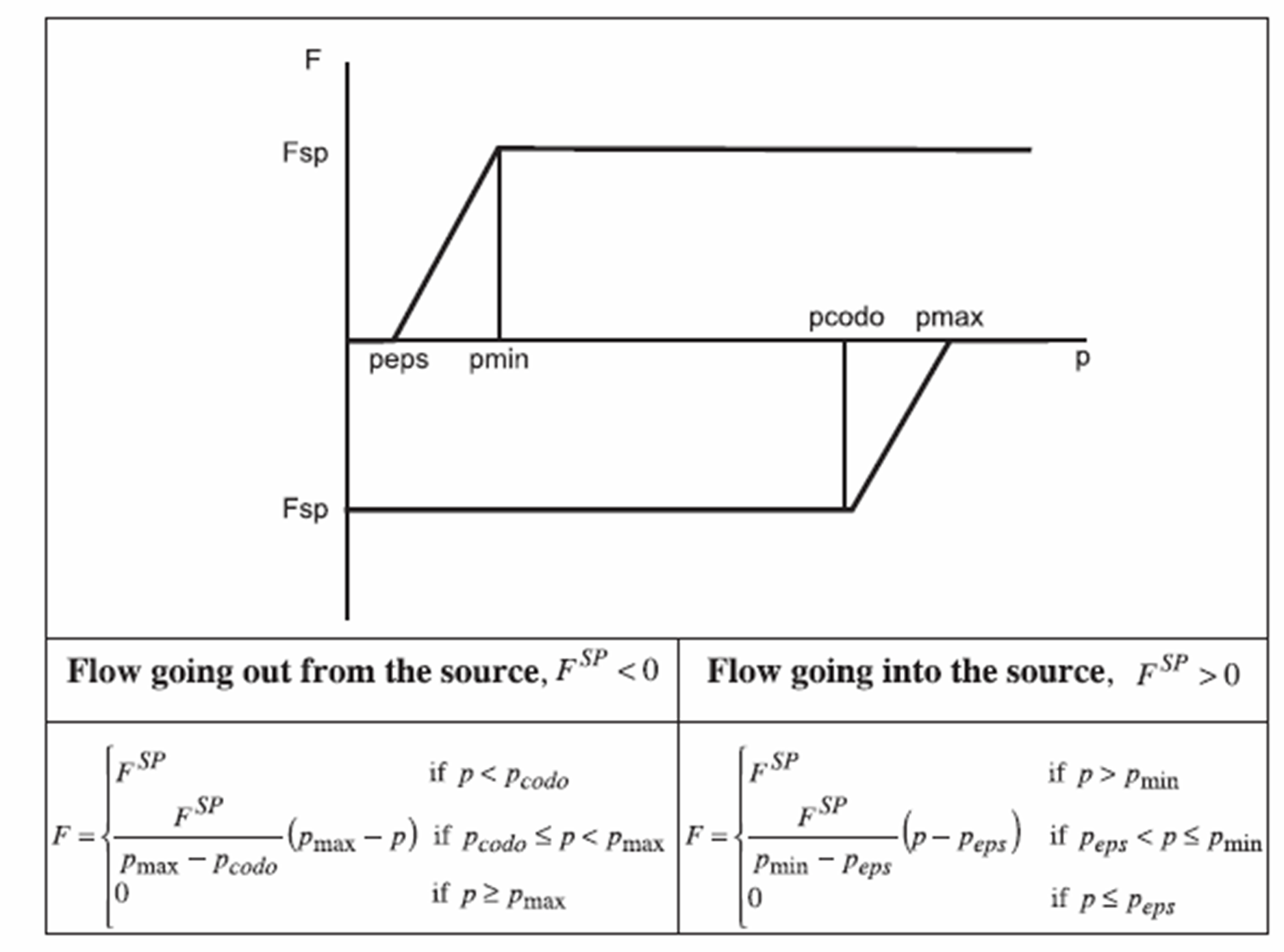

partial model pumpGasB "Partial model - Gas pump"

extends convecGasFlowB;

Real totalMolFSP( unit="mol.t-1") "Setpoint of the total molar-flow";

// Parameters of the pump constitutive relation: pmax > pcodo , pmin > peps

parameter Real pmax( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real pmin( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real pcodo( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real peps( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

protected

Real pressTo( unit="M.L-1.t-2") "Load pressure";

Real pressFrom( unit="M.L-1.t-2") "Source pressure";

Real coefPressTo;

Real coefPressFrom;

equation

// Load pressure

pressTo = if totalMolFSP > 0 then outMol.pressG else inMol.pressG;

// Source pressure

pressFrom = if totalMolFSP > 0 then inMol.pressG else outMol.pressG;

// Constitutive relation of the pump

coefPressTo = if pressTo < pcodo then

1 else

if pressTo < pmax then

(pmax-pressTo) / (pmax-pcodo) else

0;

coefPressFrom = if pressFrom > pmin then

1 else

if pressFrom > peps then

(pressFrom-peps) / (pmin-peps) else

0;

totalMolF = coefPressTo * coefPressFrom * totalMolFSP;

end pumpGasB;

JARA2i.gas.pumpMassGasB

JARA2i.gas.pumpMassGasB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | molecWeigth[nComp] | Molecular weigth of the components [M.moles-1] |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

| cutHeatFC | inHeat | Heat flow - Connector F-C. Connector for the heat convection. |

| cutReceiver | setPointSignal | Set.point signal |

model pumpMassGasB "Gas pump. Setpoint: total mass-flow"

extends pumpGasB;

cutsB.cutReceiver setPointSignal( dim=1, signal={totalMassFSP})

"Set.point signal";

Real totalMassFSP( unit="M.t-1") "Setpoint of the total mass-flow";

parameter Real molecWeigth[nComp]( unit="M.moles-1")

"Molecular weigth of the components";

equation

totalMolFSP = if totalMassFSP > 0 then

totalMolI * totalMassFSP / ( sum(molecWeigth[i]*inMol.molG[i] for i in 1:nComp) + eps) else

totalMolO * totalMassFSP / ( sum(molecWeigth[i]*outMol.molG[i] for i in 1:nComp) + eps);

end pumpMassGasB;

JARA2i.gas.pumpMolGasB

JARA2i.gas.pumpMolGasB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

| cutHeatFC | inHeat | Heat flow - Connector F-C. Connector for the heat convection. |

| cutReceiver | setPointSignal | Set.point signal |

model pumpMolGasB "Gas pump. Setpoint: total molar-flow"

extends pumpGasB;

cutsB.cutReceiver setPointSignal( dim=1, signal={totalMolFSP})

"Set.point signal";

equation

end pumpMolGasB;

JARA2i.gas.pumpVolGasB

JARA2i.gas.pumpVolGasB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | perfGasConst | Perfect-gas constant [M.L2.t-2.T-1] |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

| cutHeatFC | inHeat | Heat flow - Connector F-C. Connector for the heat convection. |

| cutReceiver | setPointSignal | Set-point signal |

model pumpVolGasB "Gas pump. Setpoint: total volumetric-flow"

extends pumpGasB;

cutsB.cutReceiver setPointSignal( dim=1, signal={totalVolFSP})

"Set-point signal";

Real totalVolFSP( unit="L3.t-1") "Setpoint of the volumetric flow";

parameter Real perfGasConst( unit="M.L2.t-2.T-1") "Perfect-gas constant";

equation

0 = if totalVolFSP > 0 then

inMol.pressG * totalVolFSP - totalMolFSP * perfGasConst * ( inMol.tempG + eps) else

outMol.pressG * totalVolFSP - totalMolFSP * perfGasConst * ( outMol.tempG + eps);

end pumpVolGasB;

JARA2i.gas.semiPerfGasCp6B

JARA2i.gas.semiPerfGasCp6B

Homogeneous mixture of semi-perfect gases.

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | molGinitial[nComp] | Number of gas moles - Initial condition [mol] | |

| Real | tempGinitial | Gas temperature - Initial condition [T] | |

| Real | perfGasConst | Constant of the perfect gases [M.L2.t-2.T-1] | |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Type | Name | Description |

|---|---|---|

| cutGasC | inMol | Gas flow - Connector Capacitive |

| cutHeatMC | inHeat | Heat flow - Connector M-C |

| cutVolConstrGas | constraintV | Volume constraint - Gas |

model semiPerfGasCp6B "Homogeneous mixture of semi-perfect gases."

extends interf.gasV1I;

parameter Real molGinitial[nComp]( unit="mol")

"Number of gas moles - Initial condition";

parameter Real tempGinitial( unit="T")

"Gas temperature - Initial condition";

parameter Real perfGasConst( unit="M.L2.t-2.T-1")

"Constant of the perfect gases";

parameter Real CpCoefN[nComp,7] "Coefficients of the molar heat capacity at constant pressure

CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6";

parameter Real eps( unit="") = 1.E-10

"Small constant to avoid by-zero division";

parameter Real molEnthalpyRef[nComp]( unit="M.L2.t-2.mol-1") = zeros(nComp)

"Molar enthalpy of the components at the reference temperature";

parameter Real tempRef( unit="T") = 298

"Reference temperature for enthalpy";

Real molG[ nComp]( unit="mol", start=molGinitial, fixed=true)

"Number of gas moles"; //CCC

Real tempG( unit="K", start=tempGinitial, fixed=true)

" Gas temperature";

Real fluidV( unit="m^3") "Gas volume";

protected

Real dIntEnergy( unit="M.L2.t-3")

"Derivative of the total internal energy";

Real molIntEnergy[ nComp]( unit="M.L2.t-2.mol-1")

"Molar internal energy of the components";

Real aux[ nComp];

Real vesselV;

equation

// Variable of the volume constraint connector

vesselV = constraintV.vcF;

// Relationship among the interface variables

inHeat.matter = molG;

inMol.molG = molG;

inHeat.temp = tempG;

inMol.tempG = tempG;

// constraintV.press = inMol.pressG;

constraintV.vcE[3] = inMol.pressG;

// Molar balance

der(molG) = inMol.molGF;

// Energy balance

dIntEnergy = inMol.energyGF + inHeat.heatF;

// The gas volume is equal to the control-volume volume

fluidV = vesselV;

// State equation of the perfect gases

inMol.pressG * ( fluidV + eps) = sum(inMol.molG[i] for i in 1:nComp) * perfGasConst * inMol.tempG;

// Relationship between the molar internal energy and the temperature

for i in 1:nComp loop

molIntEnergy[i] = molEnthalpyRef[i] - perfGasConst * inMol.tempG +

CpCoefN[i,1] * ( (inMol.tempG+eps) - tempRef) +

CpCoefN[i,2] * 1/2 * ( (inMol.tempG+eps)^ 2 - tempRef^ 2) +

CpCoefN[i,3] * 1/3 * ( (inMol.tempG+eps)^ 3 - tempRef^ 3) +

CpCoefN[i,4] * 1/4 * ( (inMol.tempG+eps)^ 4 - tempRef^ 4) +

CpCoefN[i,5] * 1/5 * ( (inMol.tempG+eps)^ 5 - tempRef^ 5) +

CpCoefN[i,6] * 1/6 * ( (inMol.tempG+eps)^ 6 - tempRef^ 6) +

CpCoefN[i,7] * 1/7 * ( (inMol.tempG+eps)^ 7 - tempRef^ 7);

end for;

for i in 1:nComp loop

aux[i] = CpCoefN[i,1] +

CpCoefN[i,2] * inMol.tempG +

CpCoefN[i,3] * inMol.tempG^ 2 +

CpCoefN[i,4] * inMol.tempG^ 3 +

CpCoefN[i,5] * inMol.tempG^ 4 +

CpCoefN[i,6] * inMol.tempG^ 5 +

CpCoefN[i,7] * inMol.tempG^ 6 -

perfGasConst;

end for;

dIntEnergy = sum(inMol.molGF[i]*molIntEnergy[i] for i in 1:nComp) +

sum(( inMol.molG[i] + eps) * aux[i] for i in 1:nComp) * der(tempG);

end semiPerfGasCp6B;

JARA2i.gas.semiPerfGasCp6VB

JARA2i.gas.semiPerfGasCp6VB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | perfGasConst | Constant of the perfect gases [M.L2.t-2.T-1] | |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6 | |

| Real | eps | 1.E-10 | Small constant to avoid by-zero division |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy of the components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for enthalpy [T] |

| Real | vesselVolumeInitial | Vessel volume [L3] | |

| Real | molGinitial[nComp] | Initial condition [mol] | |

| Real | tempGinitial | Initial condition [T] |

| Type | Name | Description |

|---|---|---|

| cutGasC | inMol | Gas flow - Connector Capacitive |

| cutHeatMC | inHeat | Heat flow - Connector M-C |

model semiPerfGasCp6VB

"Homogeneous mixture of semi-perfect gases inside a vessel."

extends interf.gas1I;

parameter Real perfGasConst( unit="M.L2.t-2.T-1")

"Constant of the perfect gases";

parameter Real CpCoefN[nComp,7] "Coefficients of the molar heat capacity at constant pressure

CpMol[i] = CpCoefN[i,1] + CpCoefN[i,2]*T + ... + CpCoefN[i,7]*T**6";

parameter Real eps( unit="") = 1.E-10

"Small constant to avoid by-zero division";

parameter Real molEnthalpyRef[nComp]( unit="M.L2.t-2.mol-1") = zeros(nComp)

"Molar enthalpy of the components at the reference temperature";

parameter Real tempRef( unit="T") = 298

"Reference temperature for enthalpy";

parameter Real vesselVolumeInitial( unit="L3") "Vessel volume";

parameter Real molGinitial[nComp]( unit="mol") "Initial condition";

parameter Real tempGinitial( unit="T") "Initial condition";

semiPerfGasCp6B semiPerfGas( nComp=nComp,perfGasConst=perfGasConst,CpCoefN=CpCoefN,eps=eps,

molEnthalpyRef=molEnthalpyRef,tempRef=tempRef,

molGinitial=molGinitial, tempGinitial=tempGinitial);

vesselGasB vessel( vesselVolumeInitial=vesselVolumeInitial);

equation

connect( semiPerfGas.constraintV, vessel.constraintV);

connect( semiPerfGas.inMol, inMol);

connect( semiPerfGas.inHeat, inHeat);

end semiPerfGasCp6VB;

JARA2i.gas.sourceGasFB

JARA2i.gas.sourceGasFB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for the enthalpy [T] |

| Real | pmax | 1.0E6 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | pcodo | 9.5E5 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | pmin | 1 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | peps | 0.2 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | eps | 1.E-8 | Small constant to avoid by-zero division |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive |

model sourceGasFB "Gas-flow source"

extends interf.gasFlow1I;

Real molFractSP[ nComp]( unit="") "Setpoint of the molar fraction";

Real tempFSP( unit="T") "Setpoint of the flow temperature";

Real totalMolFSP( unit="mol.t-1")

"Setpoint of the total molar-flow";

parameter Real CpCoefN[nComp,7] "Coefficients of the molar heat capacity at constant pressure

Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6";

parameter Real molEnthalpyRef[nComp]( unit="M.L2.t-2.mol-1") = zeros(nComp)

"Molar enthalpy at the reference temperature";

parameter Real tempRef( unit="T") = 298

"Reference temperature for the enthalpy";

parameter Real pmax( unit="M.L-1.t-2") = 1.0E6

"Parameter of the source constitutive relation";

parameter Real pcodo( unit="M.L-1.t-2") = 9.5E5

"Parameter of the source constitutive relation";

parameter Real pmin( unit="M.L-1.t-2") = 1

"Parameter of the source constitutive relation";

parameter Real peps( unit="M.L-1.t-2") = 0.2

"Parameter of the source constitutive relation";

parameter Real eps( unit="") = 1.E-8

"Small constant to avoid by-zero division";

Real tempF( unit="T") "Flow temperature";

protected

Boolean flowIsPosit( start = true) "Flow direction";

Real totalMolF( unit="mol.t-1") "Total molar flow";

Real totalMol( unit="mol") "Total mols";

Real molFract[ nComp]( unit="") "Molar fraction";

Real aux[ nComp];

equation

// Constitutive relation of the gas source

flowIsPosit = totalMolFSP > 0;

totalMolF = if flowIsPosit and inMol.pressG > pmin then

totalMolFSP else

if flowIsPosit and inMol.pressG > peps then

totalMolFSP * ( inMol.pressG - peps) / ( pmin - peps) else

if flowIsPosit then

0 else

if inMol.pressG < pcodo then

totalMolFSP else

if inMol.pressG < pmax then

totalMolFSP * ( pmax - inMol.pressG) / ( pmax - pcodo) else

0;

// Total mols

totalMol = sum(inMol.molG[i] for i in 1:nComp);

// Molar fraction

molFract = inMol.molG / ( totalMol + eps);

// Composition of the mass flow

if nComp > 1 then

for i in 1:(nComp-1) loop

inMol.molGF[i] = if flowIsPosit then

molFract[i] * totalMolF else

molFractSP[i] * totalMolF;

end for;

end if;

// Total molar flow

totalMolF = sum(inMol.molGF[i] for i in 1:nComp);

// Flow temperature

tempF = if flowIsPosit then inMol.tempG else tempFSP;

// Enthalpy flow

for i in 1:nComp loop

aux[i] = molEnthalpyRef[i] +

CpCoefN[i,1] * ( tempF - tempRef) +

CpCoefN[i,2] * 1/2 * ( tempF^ 2 - tempRef^ 2) +

CpCoefN[i,3] * 1/3 * ( tempF^ 3 - tempRef^ 3) +

CpCoefN[i,4] * 1/4 * ( tempF^ 4 - tempRef^ 4) +

CpCoefN[i,5] * 1/5 * ( tempF^ 5 - tempRef^ 5) +

CpCoefN[i,6] * 1/6 * ( tempF^ 6 - tempRef^ 6) +

CpCoefN[i,7] * 1/7 * ( tempF^ 7 - tempRef^ 7);

end for;

inMol.energyGF = sum(inMol.molGF[i] * aux[i] for i in 1:nComp);

end sourceGasFB;

JARA2i.gas.sourceMassGasFB

JARA2i.gas.sourceMassGasFB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for the enthalpy [T] |

| Real | pmax | 1.0E6 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | pcodo | 9.5E5 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | pmin | 1 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | peps | 0.2 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | eps | 1.E-8 | Small constant to avoid by-zero division |

| Real | molecWeigth[nComp] | Molecular weigth of the components [M.mol-1] |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive |

| cutReceiver | setPointSignal | Setpoint signals {totalMassFSP, massFractSP[:], tempFSP} |

model sourceMassGasFB

"Gas-flow source. Setpoint: total mass-flow, flow molar-fraction and flow temperature."

extends sourceGasFB;

cutsB.cutReceiver setPointSignal( dim=nComp+2)

"Setpoint signals {totalMassFSP, massFractSP[:], tempFSP}";

Real totalMassFSP( unit="M.t-1")

"Setpoint of the total mass flow";

Real massFractSP[ nComp]( unit="") "Setpoint of the mass fraction";

parameter Real molecWeigth[ nComp]( unit="M.mol-1")

"Molecular weigth of the components";

protected

Real auxMW;

equation

setPointSignal.signal[1] = totalMassFSP;

setPointSignal.signal[2:(nComp+1)] = massFractSP[:];

setPointSignal.signal[nComp+2] = tempFSP;

auxMW = sum(massFractSP[i]/molecWeigth[i] for i in 1:nComp);

for i in 1:nComp loop

molFractSP[i] = massFractSP[i] / ( molecWeigth[i] * auxMW);

end for;

totalMolFSP = auxMW * totalMassFSP;

end sourceMassGasFB;

JARA2i.gas.sourceMolGasFB

JARA2i.gas.sourceMolGasFB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for the enthalpy [T] |

| Real | pmax | 1.0E6 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | pcodo | 9.5E5 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | pmin | 1 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | peps | 0.2 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | eps | 1.E-8 | Small constant to avoid by-zero division |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive |

| cutReceiver | setPointSignal | Setpoint signals {totalMolFSP, molFractSP[:], tempFSP} |

model sourceMolGasFB

"Gas-flow source. Setpoint: total molar-flow, flow molar-fraction and flow temperature."

extends sourceGasFB;

cutsB.cutReceiver setPointSignal( dim=nComp+2)

"Setpoint signals {totalMolFSP, molFractSP[:], tempFSP}";

equation

setPointSignal.signal[1] = totalMolFSP;

setPointSignal.signal[2:(nComp+1)] = molFractSP[:];

setPointSignal.signal[nComp+2] = tempFSP;

end sourceMolGasFB;

JARA2i.gas.sourcePressGasB

JARA2i.gas.sourcePressGasB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Type | Name | Description |

|---|---|---|

| cutGasC | inMol | Gas flow - Connector Capacitive |

| cutHeatMC | inHeat | Heat flow - Connector M-C |

partial model sourcePressGasB "Partial model - Pressure source. The across variables should be a funcion of time and state variables." extends interf.gas1I; equation // Relationship among the interface variables inMol.molG = inHeat.matter; inMol.tempG = inHeat.temp; end sourcePressGasB;

JARA2i.gas.sourceVolGasFB

JARA2i.gas.sourceVolGasFB

Gas-flow source. Setpoint: total volume-flow, flow molar-fraction and flow temperature

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | CpCoefN[nComp, 7] | Coefficients of the molar heat capacity at constant pressure Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | molEnthalpyRef[nComp] | zeros(nComp) | Molar enthalpy at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for the enthalpy [T] |

| Real | pmax | 1.0E6 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | pcodo | 9.5E5 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | pmin | 1 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | peps | 0.2 | Parameter of the source constitutive relation [M.L-1.t-2] |

| Real | eps | 1.E-8 | Small constant to avoid by-zero division |

| Real | perfGasConst | Constant of the perfect gases |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive |

| cutReceiver | setPointSignal | Setpoint signal: { totalVolFSP, molFractSP[:], tempFSP, pressFSP} |

model sourceVolGasFB

"Gas-flow source. Setpoint: total volume-flow, flow molar-fraction and flow temperature"

extends sourceGasFB;

cutsB.cutReceiver setPointSignal( dim=nComp+3)

"Setpoint signal: { totalVolFSP, molFractSP[:], tempFSP, pressFSP}";

Real totalVolFSP "Setpoint of the total volume flow";

Real pressFSP "Setpoint of the gas flow pressure";

parameter Real perfGasConst "Constant of the perfect gases";

equation

setPointSignal.signal[1] = totalVolFSP;

setPointSignal.signal[2:(nComp+1)] = molFractSP[:];

setPointSignal.signal[nComp+2] = tempFSP;

setPointSignal.signal[nComp+3] = pressFSP;

0 = if totalVolFSP > 0 then

inMol.pressG * totalVolFSP - totalMolFSP * perfGasConst * inMol.tempG else

pressFSP * totalVolFSP - totalMolFSP * perfGasConst * tempFSP;

end sourceVolGasFB;

JARA2i.gas.vesselGasB

JARA2i.gas.vesselGasB

| vesselVolume | Recipient volume. |

| Type | Name | Default | Description |

|---|---|---|---|

| Boolean | Ejs | false | Global parameter - Runtime interactive simulation |

| Boolean | Sysquake | false | Global parameter - Batch interactive simulation |

| Real | vesselVolumeInitial | Vessel volume - Initial condition [L3] |

| Type | Name | Description |

|---|---|---|

| cutVolConstrVessel | constraintV | Volume constraint - Vessel. |

model vesselGasB "Vessel with a constant volume."

extends interf.vesselI;

outer parameter Boolean Ejs=false

"Global parameter - Runtime interactive simulation";

outer parameter Boolean Sysquake=false

"Global parameter - Batch interactive simulation";

parameter Real vesselVolumeInitial(unit="L3")

"Vessel volume - Initial condition";

Real vesselVolume(start=vesselVolumeInitial)

"Vessel volume - Interactive Variable";

equation

// Interactive parameter for Ejs

if Ejs then

der(vesselVolume) = 0;

end if;

// Sysquake

if Sysquake then

vesselVolume = vesselVolumeInitial;

end if;

// The vessel volume is a constant

// constraintV.vesselV = vesselVolume;

constraintV.vcE[1] = vesselVolume;

end vesselGasB;