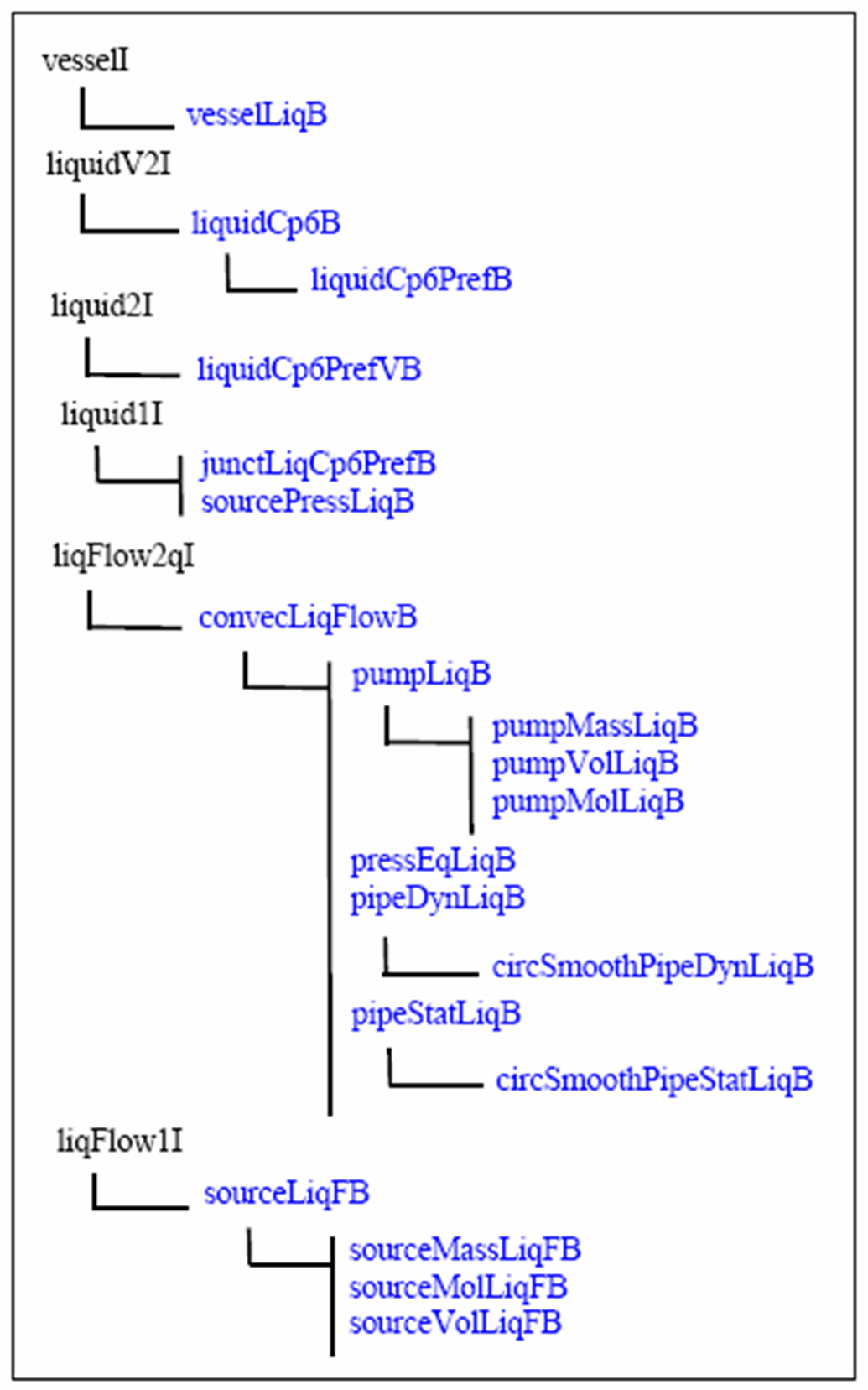

This package contains some models of liquid control volumes (CVs), liquid mixtures TP (e.g., liquid-flow by convection, valves, pumps, etc.) and boundary conditions (i.e., liquid-flow and pressure sources).

The mixtures of liquids are considered ideal and they can be composed of an arbitrary number of components.

| Name | Description |

|---|---|

| Dynamic linear-momentum balance. Circular pipe with a smooth wall | |

| Steady-state balance of linear momentum. Circular pipe with smooth wall and full of liquid | |

| Partial model: convective flow of liquid. | |

| Model of the flow junction | |

| Control volume containing a liquid mixture. | |

| Control volume containing a liquid mixture. The pressure on the liquid surface is constant. | |

| Liquid mixture contained in a control volume in mechanical equilibrium with a gas whose properties are not modeled. | |

| Partial model - Dynamic balance of linear momentum | |

| Steady-state balance of linear momentum | |

| Liquid flowing through a pipe | |

| Partial model: liquid pump | |

| Liquid pump. Setpoint: mass flow | |

| Liquid pump. Setpoint: molar flow | |

| Liquid pump. Setpoint: volumetric flow | |

| Partial model: liquid source | |

| Liquid source. Setpoints: total mass, mass fraction and temperature | |

| Liquid source. Setpoints: total molar flow, molar fraction and temperature. | |

| Pressure source. | |

| Liquid source. Setpoints: total volumetric flow, volume fraction and temperature. | |

| Vessel with a constant volume. |

JARA2i.liq.circSmoothPipeDynLiqB

JARA2i.liq.circSmoothPipeDynLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | length | Pipe length [L] | |

| Real | section | Pipe cross-section [L2] | |

| Real | wettedArea | Wetted pipe surface [L2] | |

| Real | heigthI | 0 | Heigth of the input control plane [L] |

| Real | heigthO | 0 | Heigth of the input control plane [L] |

| Real | density[nComp] | Density of the components [M.L-3] | |

| Real | g | 9.8 | Gravitational acceleration [L.t-2] |

| Real | epsMomentum | 1 | Coefficient of the fluid inertia |

| Real | lamReynolds | 2100 | Critical value of the Reynolds number |

| Real | turReynolds | 2500 | Critical value of the Reynolds number |

| Real | radiusPipe | (section/3.141592)^0.5 | Pipe radius [L] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

| cutReceiver | setPointSignal |

model circSmoothPipeDynLiqB

"Dynamic linear-momentum balance. Circular pipe with a smooth wall"

extends pipeDynLiqB;

parameter Real lamReynolds( unit="") = 2100

"Critical value of the Reynolds number";

parameter Real turReynolds( unit="") = 2500

"Critical value of the Reynolds number";

parameter Real radiusPipe( unit="L") = ( section / 3.141592)^ 0.5

"Pipe radius";

protected

Real viscosity( unit="M.L-1.t-1") "Viscosity of the liquid mixture";

Real reynolds( unit="") "Reynolds number";

Boolean laminar( start = true) "True: while laminar regime";

Boolean turbulent( start = false) "True: while turbulent regime";

equation

// Reynolds number

reynolds = 2 * radiusPipe * ( abs(veloc) + eps) * fluidDensity / ( viscosity + eps);

// Flow regime

laminar = reynolds < lamReynolds;

turbulent = reynolds > turReynolds;

// Fanning friction factor. Blasius equation for the turbulent regime

fanning = if laminar then

16 / ( abs(reynolds) + eps) else

if turbulent then

0.0791 / ( abs(reynolds)^ 0.25 + eps) else

( 16 / lamReynolds - 0.0791 / turReynolds^ 0.25) /

( lamReynolds - turReynolds) * reynolds +

( 0.0791 / turReynolds^ 0.25 * lamReynolds - 16 / lamReynolds * turReynolds) /

( lamReynolds - turReynolds);

end circSmoothPipeDynLiqB;

JARA2i.liq.circSmoothPipeStatLiqB

JARA2i.liq.circSmoothPipeStatLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | length | Pipe length [L] | |

| Real | section | Pipe cross-section [L2] | |

| Real | wettedArea | Wetted pipe surface [L2] | |

| Real | heigthI | 0 | Heigth of the input control plane [L] |

| Real | heigthO | 0 | Heigth of the input control plane [L] |

| Real | density[nComp] | Density of the components [M.L-3] | |

| Real | g | 9.8 | Gravitational acceleration [L.t-2] |

| Real | lamReynolds | 2100 | Critical value of the Reynolds number |

| Real | turReynolds | 2500 | Critical value of the Reynolds number |

| Real | radiusPipe | (section/3.141592)^0.5 | Pipe radius [L] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

| cutReceiver | setPointSignal |

model circSmoothPipeStatLiqB "Steady-state balance of linear momentum.

Circular pipe with smooth wall and full of liquid"

extends pipeStatLiqB;

parameter Real lamReynolds( unit="") = 2100

"Critical value of the Reynolds number";

parameter Real turReynolds( unit="") = 2500

"Critical value of the Reynolds number";

parameter Real radiusPipe( unit="L") = ( section / 3.141592)^ 0.5

"Pipe radius";

protected

Real viscosity( unit="M.L-1.t-1") "Viscosity of the liquid mixture";

Real reynolds( unit="") "Reynolds number";

Boolean laminar( start = true) "True: while laminar regime";

Boolean turbulent( start = false) "True: while turbulent regime";

equation

// Reynolds number

reynolds = 2 * radiusPipe * ( abs(veloc) + eps) * fluidDensity / ( viscosity + eps);

// Flow regime

laminar = reynolds < lamReynolds;

turbulent = reynolds > turReynolds;

// Fanning adimensional factor. Blasius equation for turbulent flow

fanning = if laminar then

16 / ( abs(reynolds) + eps) else

if turbulent then

0.0791 / ( abs(reynolds)^ 0.25 + eps) else

( 16 / lamReynolds - 0.0791 / turReynolds^ 0.25) /

( lamReynolds - turReynolds) * reynolds +

( 0.0791 / turReynolds^ 0.25 * lamReynolds - 16 / lamReynolds * turReynolds) /

( lamReynolds - turReynolds);

end circSmoothPipeStatLiqB;

JARA2i.liq.convecLiqFlowB

JARA2i.liq.convecLiqFlowB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

partial model convecLiqFlowB

"Partial model: convective flow of liquid."

extends interf.liqFlow2qI;

// Interactivity

outer parameter Boolean Ejs = false

"Global parameter - Runtime interactivity";

outer parameter Boolean Sysquake = false

"Global parameter - Batch interactivity";

parameter Real CpCoefMInitial[nComp,7] "Coefficients of the specific (per mass) heat capacity

CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6";

parameter Real massEnthalpyRefInitial[nComp]( unit="L2.t-2") = zeros(nComp)

"Specific (per mass) enthalpy at the reference temperature";

parameter Real tempRefInitial( unit="T") = 298

"Reference temperature for the enthalpy";

parameter Real eps( unit="") = 1.E-6

"Small constant to avoid by-zero division";

// Interactive variables

Real CpCoefM[nComp,7]( start=CpCoefMInitial) "Coefficients of the specific (per mass) heat capacity

CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6";

Real massEnthalpyRef[nComp]( unit="L2.t-2",start=massEnthalpyRefInitial)

"Specific (per mass) enthalpy at the reference temperature";

Real tempRef( unit="T",start=tempRefInitial)

"Reference temperature for the enthalpy";

protected

Real totalMassF( unit="M.t-1") "Total mass flow";

Boolean flowIsPosit( start=true) "Flow direction";

Real totalMassI( unit="M") "Total mass";

Real totalMassO( unit="M") "Total mass";

Real massEnthalpy[ nComp]( unit="L2.t-2")

"Specific (per mass) enthalpy of each component";

equation

// Ejs

if Ejs then

for i in 1:nComp loop

for j in 1:7 loop

der(CpCoefM[i,j]) = 0;

end for;

end for;

for i in 1:nComp loop

der(massEnthalpyRef[i]) = 0;

end for;

der(tempRef) = 0;

end if;

// Sysquake

if Sysquake then

CpCoefM = CpCoefMInitial;

massEnthalpyRef = massEnthalpyRefInitial;

tempRef = tempRefInitial;

end if;

// Relationship among the interface variables

for i in 1:nComp loop

inMass.massLF[i] + outMass.massLF[i] = 0;

end for;

inMass.massLF = inHeat.matterF;

outMass.energyLF + inMass.energyLF + inHeat.heatF = 0;

// Mass flow direction

flowIsPosit = totalMassF > 0;

// Total mass

totalMassI = sum(inMass.massL[i] for i in 1:nComp);

totalMassO = sum(outMass.massL[i] for i in 1:nComp);

// Flow composition

if nComp > 1 then

for i in 1:(nComp-1) loop

inHeat.matterF[i] = if flowIsPosit then

totalMassF * inMass.massL[i] / ( totalMassI + eps) else

totalMassF * outMass.massL[i] / ( totalMassO + eps);

end for;

end if;

// Total mass flow

totalMassF = sum(inHeat.matterF[i] for i in 1:nComp);

// Flow temperature

inHeat.tempF = if flowIsPosit then inMass.tempL else outMass.tempL;

// Molar internal energy as a function of the temperature

for i in 1:nComp loop

massEnthalpy[i] = massEnthalpyRef[i] +

CpCoefM[i,1] * ( inHeat.tempF - tempRef) +

CpCoefM[i,2] * 1/2 * ( inHeat.tempF^ 2 - tempRef^ 2) +

CpCoefM[i,3] * 1/3 * ( inHeat.tempF^ 3 - tempRef^ 3) +

CpCoefM[i,4] * 1/4 * ( inHeat.tempF^ 4 - tempRef^ 4) +

CpCoefM[i,5] * 1/5 * ( inHeat.tempF^ 5 - tempRef^ 5) +

CpCoefM[i,6] * 1/6 * ( inHeat.tempF^ 6 - tempRef^ 6) +

CpCoefM[i,7] * 1/7 * ( inHeat.tempF^ 7 - tempRef^ 7);

end for;

// Energy flow

sum(inHeat.matterF[i] * massEnthalpy[i] for i in 1:nComp) = if flowIsPosit then inMass.energyLF else -outMass.energyLF;

end convecLiqFlowB;

JARA2i.liq.junctLiqCp6PrefB

JARA2i.liq.junctLiqCp6PrefB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components of the liquid mixture |

| Real | sectionInitial | 1 | Cross-section of the vessel [L2] |

| Real | g | 9.8 | Gravitatorial acceleration [L.t-2] |

| Real | angle | 1.5707963 | Angle with the horizontal [rad] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | densityInitial[nComp] | Density of the pure components [M.L-3] | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | percentVolSmallStep | 0.9 | Proportion of the vessel volume that triggers the reduction in the integration step-size |

| Real | compressCoef | 1.E-8 | Numeric compressibility coefficient [L.t2.M-1] |

| Real | pressTopRef | 0 | Pressure on the liquid surface [M.L-1.t-2] |

| Real | vesselVolumeInitial | 1 | Vessel volume [L3] |

| Real | massLinitial[nComp] | Initial condition [M] | |

| Real | tempLinitial | Initial condition [T] |

| Type | Name | Description |

|---|---|---|

| cutLiquidC | inMass | Connector for the liquid flow |

model junctLiqCp6PrefB "Model of the flow junction"

extends interf.liquid1I;

parameter Real sectionInitial( unit="L2") = 1

"Cross-section of the vessel";

parameter Real g( unit="L.t-2") = 9.8

"Gravitatorial acceleration";

parameter Real angle( unit="rad") = 1.5707963

"Angle with the horizontal";

parameter Real eps( unit="") = 1.E-6

"Small constant to avoid by-zero division";

parameter Real CpCoefMInitial[nComp,7] "Coefficients of the specific (per mass) heat capacity

CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6";

parameter Real densityInitial[nComp]( unit="M.L-3")

"Density of the pure components";

parameter Real massEnthalpyRefInitial[nComp]( unit="L2.t-2") = zeros(nComp)

"Specific (per mass) enthalpy at the reference temperature";

parameter Real tempRefInitial( unit="T") = 298

"Reference temperature for the enthalpy";

parameter Real percentVolSmallStep( unit="") = 0.9 "Proportion of the vessel volume that

triggers the reduction in the integration step-size";

parameter Real compressCoef( unit="L.t2.M-1") = 1.E-8

"Numeric compressibility coefficient";

parameter Real pressTopRef( unit="M.L-1.t-2") = 0

"Pressure on the liquid surface";

parameter Real vesselVolumeInitial( unit="L3") = 1 "Vessel volume";

parameter Real massLinitial[ nComp]( unit="M") "Initial condition";

parameter Real tempLinitial( unit="T") "Initial condition";

liquidCp6PrefB liquid( nComp=nComp,sectionInitial=sectionInitial,g=g,angle=angle,eps=eps,

CpCoefMInitial=CpCoefMInitial,tempRefInitial=tempRefInitial,

massEnthalpyRefInitial=massEnthalpyRefInitial,

densityInitial = densityInitial,

compressCoef=compressCoef,percentVolSmallStep=percentVolSmallStep,

pressTopReference=pressTopRef,

massLinitial=massLinitial, tempLinitial=tempLinitial);

vesselLiqB vessel( vesselVolumeInitial=vesselVolumeInitial);

equation

connect( liquid.constraintV, vessel.constraintV);

connect( liquid.inMassBot, inMass);

end junctLiqCp6PrefB;

JARA2i.liq.liquidCp6B

JARA2i.liq.liquidCp6B

| section | Cross-section of the vessel. |

| density[nComp] | Density of the pure components. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | massLinitial[nComp] | Initial condition - Mass inside the CV [M] | |

| Real | tempLinitial | Initial condition - Temperature of the CV [T] | |

| Real | sectionInitial | 1 | Initial cross-section of the vessel [L2] |

| Real | g | 9.8 | Gravitatorial acceleration [L.t-2] |

| Real | angle | 1.5707963 | Angle with the horizontal [rad] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | densityInitial[nComp] | Density of the pure components [M.L-3] | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | percentVolSmallStep | 0.9 | Proportion of the vessel volume that triggers the reduction in the integration step-size |

| Real | compressCoef | 1.E-8 | Numeric compressibility coefficient [L.t2.M-1] |

| Type | Name | Description |

|---|---|---|

| cutLiquidC | inMassTop | Connector for the liquid flow |

| cutLiquidC | inMassBot | Connector for the liquid flow |

| cutHeatMC | inHeat | Connector for the heat flow |

| cutVolConstrLiq | constraintV | Connector for the volume constraint - Liquid |

model liquidCp6B "Control volume containing a liquid mixture."

extends interf.liquidV2I;

// Interactivity

outer parameter Boolean Ejs = false

"Global parameter - Runtime interactivity";

outer parameter Boolean Sysquake = false

"Global parameter - Batch interactivity";

parameter Real massLinitial[ nComp]( unit="M")

"Initial condition - Mass inside the CV";

parameter Real tempLinitial( unit="T")

"Initial condition - Temperature of the CV";

parameter Real sectionInitial( unit="L2") = 1

"Initial cross-section of the vessel";

parameter Real g( unit="L.t-2") = 9.8

"Gravitatorial acceleration";

parameter Real angle( unit="rad") = 1.5707963

"Angle with the horizontal";

parameter Real eps( unit="") = 1.E-6

"Small constant to avoid by-zero division";

parameter Real CpCoefMInitial[nComp,7] "Coefficients of the specific (per mass) heat capacity

CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6";

parameter Real densityInitial[nComp]( unit="M.L-3")

"Density of the pure components";

parameter Real massEnthalpyRefInitial[nComp]( unit="L2.t-2") = zeros(nComp)

"Specific (per mass) enthalpy at the reference temperature";

parameter Real tempRefInitial( unit="T") = 298

"Reference temperature for the enthalpy";

parameter Real percentVolSmallStep( unit="") = 0.9 "Proportion of the vessel volume that

triggers the reduction in the integration step-size";

parameter Real compressCoef( unit="L.t2.M-1")= 1.E-8

"Numeric compressibility coefficient";

Real massL[nComp]( unit="M", start=massLinitial, fixed=true)

"Liquid mass inside the CV";

Real tempL( unit="K", start=tempLinitial, fixed=true)

"Water temperature";

Real section( unit="L2", start=sectionInitial)

"Cross-section of the vessel";

Real CpCoefM[nComp,7]( start=CpCoefMInitial) "Coefficients of the specific (per mass) heat capacity

CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6";

Real density[nComp]( unit="M.L-3", start=densityInitial)

"Density of the pure components";

Real massEnthalpyRef[nComp]( unit="L2.t-2", start=massEnthalpyRefInitial)

"Specific (per mass) enthalpy at the reference temperature";

Real tempRef( unit="T", start=tempRefInitial)

"Reference temperature for the enthalpy";

Real liqHeight( unit="L") "Liquid level";

Real fluidV( unit="L3") "Liquid volume";

Boolean isFull( start=false) "Is the vessel full of liquid?";

protected

Real dEnthalpy( unit="M.L2.t-3")

"Derivative of the total enthalpy";

Real massEnthalpy[ nComp]( unit="L2.t-2")

"Specific (per mass) enthalpy of each component";

Real fluidVun( unit="L3") "Fluid volume (unbounded)";

Real parcFluidV[ nComp]( unit="L3") "Volume of each component";

Real dummyFrec( start=0, fixed=true) "Dummy variable";

Boolean integStepIsSmall( start=false, fixed=true)

"Control of the integration step-size";

Real timeScale( unit="T", start=1)

"Control of the integration step-size";

Real aux[ nComp];

Real vesselV "Vessel volume";

Real pressTopRef "Pressure at the liquid surface";

equation

// Ejs

if Ejs then

der(section) = 0;

for i in 1:nComp loop

der(density[i]) = 0;

der(massEnthalpyRef[i]) = 0;

end for;

der(tempRef) = 0;

for i in 1:nComp loop

for j in 1:7 loop

der(CpCoefM[i,j]) = 0;

end for;

end for;

end if;

// Sysquake

if Sysquake then

section = sectionInitial;

density = densityInitial;

massEnthalpyRef = massEnthalpyRefInitial;

tempRef = tempRefInitial;

CpCoefM = CpCoefMInitial;

end if;

// Variables of the volume constraint connector

vesselV = constraintV.vcE[1];

pressTopRef = constraintV.vcE[3];

fluidV = constraintV.vcF;

// Relationship among the interface variables

inMassTop.massL = massL;

inMassBot.massL = massL;

inHeat.matter = massL;

inMassTop.tempL = tempL;

inMassBot.tempL = tempL;

inHeat.temp = tempL;

// Mass balance

der(massL) = inMassTop.massLF + inMassBot.massLF;

// Energy balance

dEnthalpy = inMassBot.energyLF + inMassTop.energyLF + inHeat.heatF;

// Specific (per mass) internal energy of each component

for i in 1:nComp loop

massEnthalpy[i] = massEnthalpyRef[i] +

CpCoefM[i,1] * ( ( inHeat.temp + eps) - tempRef) +

CpCoefM[i,2] * 1/2 * ( ( inHeat.temp + eps)^ 2 - tempRef^ 2) +

CpCoefM[i,3] * 1/3 * ( ( inHeat.temp + eps)^ 3 - tempRef^ 3) +

CpCoefM[i,4] * 1/4 * ( ( inHeat.temp + eps)^ 4 - tempRef^ 4) +

CpCoefM[i,5] * 1/5 * ( ( inHeat.temp + eps)^ 5 - tempRef^ 5) +

CpCoefM[i,6] * 1/6 * ( ( inHeat.temp + eps)^ 6 - tempRef^ 6) +

CpCoefM[i,7] * 1/7 * ( ( inHeat.temp + eps)^ 7 - tempRef^ 7);

end for;

for i in 1:nComp loop

aux[i] = CpCoefM[i,1] +

CpCoefM[i,2] * inHeat.temp +

CpCoefM[i,3] * inHeat.temp^ 2 +

CpCoefM[i,4] * inHeat.temp^ 3 +

CpCoefM[i,5] * inHeat.temp^ 4 +

CpCoefM[i,6] * inHeat.temp^ 5 +

CpCoefM[i,7] * inHeat.temp^ 6;

end for;

dEnthalpy = sum((inMassTop.massLF[i] + inMassBot.massLF[i]) * massEnthalpy[i] for i in 1:nComp) +

sum((inHeat.matter[i] + eps) * aux[i] for i in 1:nComp) * der(tempL);

// Volume of each component. Total volume

for i in 1:nComp loop

parcFluidV[i] * density[i] = inHeat.matter[i];

end for;

fluidVun = sum(parcFluidV[i] for i in 1:nComp);

fluidV = if isFull then vesselV else fluidVun;

// Liquid heigth

liqHeight = fluidV / section;

// Is the control volume full of liquid?

isFull = fluidVun > vesselV;

// The integration step-size is reduced when the liquid volume is close to the vessel volume

when pre(integStepIsSmall) and fluidVun < percentVolSmallStep * vesselV or

not pre(integStepIsSmall) and not fluidVun < percentVolSmallStep * vesselV then

timeScale = if pre(integStepIsSmall) and fluidVun < percentVolSmallStep * vesselV then

1 else compressCoef;

integStepIsSmall = not pre(integStepIsSmall);

end when;

der(dummyFrec) = sin(time / timeScale);

// Pressure at the liquid bottom

inMassBot.pressL = g * sum(inHeat.matter[i] for i in 1:nComp) * sin(angle) / section + inMassTop.pressL;

// Pressure at the liquid surface (upper part of the liquid)

inMassTop.pressL = if isFull then

( fluidVun / vesselV - 1) / compressCoef else

pressTopRef;

end liquidCp6B;

JARA2i.liq.liquidCp6PrefB

JARA2i.liq.liquidCp6PrefB

| section | Cross-section of the vessel. |

| density[nComp] | Density of the pure components. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | massLinitial[nComp] | Initial condition - Mass inside the CV [M] | |

| Real | tempLinitial | Initial condition - Temperature of the CV [T] | |

| Real | sectionInitial | 1 | Initial cross-section of the vessel [L2] |

| Real | g | 9.8 | Gravitatorial acceleration [L.t-2] |

| Real | angle | 1.5707963 | Angle with the horizontal [rad] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | densityInitial[nComp] | Density of the pure components [M.L-3] | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | percentVolSmallStep | 0.9 | Proportion of the vessel volume that triggers the reduction in the integration step-size |

| Real | compressCoef | 1.E-8 | Numeric compressibility coefficient [L.t2.M-1] |

| Real | pressTopReference | 0 | Pressure on the liquid surface [M.L-1.t-2] |

| Type | Name | Description |

|---|---|---|

| cutLiquidC | inMassTop | Connector for the liquid flow |

| cutLiquidC | inMassBot | Connector for the liquid flow |

| cutHeatMC | inHeat | Connector for the heat flow |

| cutVolConstrLiq | constraintV | Connector for the volume constraint - Liquid |

model liquidCp6PrefB

"Control volume containing a liquid mixture. The pressure on the liquid surface is constant."

extends liquidCp6B;

parameter Real pressTopReference( unit="M.L-1.t-2") = 0

"Pressure on the liquid surface";

equation

pressTopRef = pressTopReference;

end liquidCp6PrefB;

JARA2i.liq.liquidCp6PrefVB

JARA2i.liq.liquidCp6PrefVB

This class models a liquid mixture.

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components of the liquid mixture |

| Real | sectionInitial | 1 | Initial cross-section of the vessel [L2] |

| Real | g | 9.8 | Gravitatorial acceleration [L.t-2] |

| Real | angle | 1.5707963 | Angle with the horizontal [rad] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | densityInitial[nComp] | Density of the pure components [M.L-3] | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | percentVolSmallStep | 0.9 | Proportion of the vessel volume that triggers the reduction in the integration step-size |

| Real | compressCoef | 1.E-8 | Numeric compressibility coefficient [L.t2.M-1] |

| Real | pressTopReference | 0 | Pressure on the liquid surface [M.L-1.t-2] |

| Real | vesselVolumeInitial | 1 | Initial vessel volume [L3] |

| Real | massLinitial[nComp] | Initial condition [M] | |

| Real | tempLinitial | Initial condition [T] |

| Type | Name | Description |

|---|---|---|

| cutLiquidC | inMassTop | Connector for the liquid flow |

| cutLiquidC | inMassBot | Connector for the liquid flow |

| cutHeatMC | inHeat | Connector for the heat flow |

model liquidCp6PrefVB

"Liquid mixture contained in a control volume in mechanical equilibrium with a gas whose properties are not modeled."

extends interf.liquid2I;

parameter Real sectionInitial( unit="L2") = 1

"Initial cross-section of the vessel";

parameter Real g( unit="L.t-2") = 9.8

"Gravitatorial acceleration";

parameter Real angle( unit="rad") = 1.5707963

"Angle with the horizontal";

parameter Real eps( unit="") = 1.E-6

"Small constant to avoid by-zero division";

parameter Real CpCoefMInitial[nComp,7] "Coefficients of the specific (per mass) heat capacity

CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6";

parameter Real densityInitial[nComp]( unit="M.L-3")

"Density of the pure components";

parameter Real massEnthalpyRefInitial[nComp]( unit="L2.t-2") = zeros(nComp)

"Specific (per mass) enthalpy at the reference temperature";

parameter Real tempRefInitial( unit="T") = 298

"Reference temperature for the enthalpy";

parameter Real percentVolSmallStep( unit="") = 0.9 "Proportion of the vessel volume that

triggers the reduction in the integration step-size";

parameter Real compressCoef( unit="L.t2.M-1") = 1.E-8

"Numeric compressibility coefficient";

parameter Real pressTopReference( unit="M.L-1.t-2") = 0

"Pressure on the liquid surface";

parameter Real vesselVolumeInitial( unit="L3") = 1 "Initial vessel volume";

parameter Real massLinitial[ nComp]( unit="M") "Initial condition";

parameter Real tempLinitial( unit="T") "Initial condition";

liquidCp6PrefB liquid( nComp=nComp,sectionInitial=sectionInitial,g=g,angle=angle,eps=eps,

CpCoefMInitial=CpCoefMInitial, tempRefInitial=tempRefInitial,

massEnthalpyRefInitial=massEnthalpyRefInitial,

densityInitial = densityInitial,

compressCoef=compressCoef,percentVolSmallStep=percentVolSmallStep,

pressTopReference=pressTopReference,

massLinitial=massLinitial, tempLinitial=tempLinitial);

vesselLiqB vessel( vesselVolumeInitial=vesselVolumeInitial);

equation

connect( liquid.constraintV, vessel.constraintV);

connect( liquid.inMassTop, inMassTop);

connect( liquid.inMassBot, inMassBot);

connect( liquid.inHeat, inHeat);

end liquidCp6PrefVB;

JARA2i.liq.pipeDynLiqB

JARA2i.liq.pipeDynLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | length | Pipe length [L] | |

| Real | section | Pipe cross-section [L2] | |

| Real | wettedArea | Wetted pipe surface [L2] | |

| Real | heigthI | 0 | Heigth of the input control plane [L] |

| Real | heigthO | 0 | Heigth of the input control plane [L] |

| Real | density[nComp] | Density of the components [M.L-3] | |

| Real | g | 9.8 | Gravitational acceleration [L.t-2] |

| Real | epsMomentum | 1 | Coefficient of the fluid inertia |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

| cutReceiver | setPointSignal |

partial model pipeDynLiqB

"Partial model - Dynamic balance of linear momentum"

extends convecLiqFlowB;

Real valveOpeningSP( unit="") "Setpoint of the valve opening";

parameter Real length( unit="L") "Pipe length";

parameter Real section( unit="L2") "Pipe cross-section";

parameter Real wettedArea( unit="L2") "Wetted pipe surface";

parameter Real heigthI( unit="L") = 0

"Heigth of the input control plane";

parameter Real heigthO( unit="L") = 0

"Heigth of the input control plane";

parameter Real density[ nComp]( unit="M.L-3") "Density of the components";

parameter Real g( unit="L.t-2") = 9.8

"Gravitational acceleration";

parameter Real epsMomentum( unit="") = 1

"Coefficient of the fluid inertia";

cutsB.cutReceiver setPointSignal( dim=1, signal={valveOpeningSP});

protected

Real veloc( unit="L.t-1") "Flow velocity";

Real linMomentum( unit="M.L.t-1") "Lineal momentum";

Real fricForce( unit="M.L.t-2") "Force of friction";

Real pressForce( unit="M.L.t-2")

"Force due to the pressure difference";

Real gravForce( unit="M.L.t-2") "Gravitational force";

Real totalForce( unit="M.L.t-2") "Total force";

Real fluidDensity( unit="M.L-3") "Fluid density";

Real fanning( unit="") "Fanning adimensional factor";

Real parcFluidV[ nComp]( unit="L3") "Volume of each component";

Real fluidVolume( unit="L3") "Total volume";

Real massFullPipe( unit="M") "Mass inside the full pipe";

Real massLiqPipe( unit="M") "Liquid mass inside the pipe";

Real totalMassI( unit="M") "Total mass at connector inMass";

Real totalMassO( unit="M") "Total mass at connector outMass";

Real valveOpening( unit="") "Bounded valve opening";

equation

// Parcial volume of each component

for i in 1:nComp loop

parcFluidV[i] * density[i] = if linMomentum>0 then inMass.massL[i] else outMass.massL[i];

end for;

// Fluid volume

fluidVolume = sum(parcFluidV[i] for i in 1:nComp);

// Total mass at connectors

totalMassI = sum(inMass.massL[i] for i in 1:nComp);

totalMassO = sum(outMass.massL[i] for i in 1:nComp);

// Fluid density

fluidDensity = if linMomentum > 0 then

totalMassI / ( fluidVolume + eps) else

totalMassO / ( fluidVolume + eps);

// Force due to the pressure difference

pressForce = section * ( inMass.pressL - outMass.pressL);

// Gravitational force

gravForce = massLiqPipe * g * ( heigthI - heigthO) / length;

massFullPipe = fluidDensity * section * length;

massLiqPipe = if heigthI > heigthO and totalMassI > massFullPipe or

heigthO > heigthI and totalMassO > massFullPipe then

massFullPipe else

if heigthI > heigthO then

totalMassI else

totalMassO;

// Friction force

fricForce = if linMomentum > 0 then

-wettedArea * 0.5 * fluidDensity * veloc^ 2 * fanning else

wettedArea * 0.5 * fluidDensity * veloc^ 2 * fanning;

// Bounding of the valve opening

valveOpening = if valveOpeningSP > 1 then

1 else

if valveOpeningSP < 0 then

0 else

valveOpeningSP;

// Linear momentum balance

totalForce = fricForce + valveOpening^ 2 * ( pressForce + gravForce);

epsMomentum * der(linMomentum) = totalForce;

when linMomentum > 0 and not ( sum(inMass.massL[i] for i in 1:nComp) > 0) or

linMomentum < 0 and not ( sum(outMass.massL[i] for i in 1:nComp) > 0) or

not valveOpeningSP > 0 then

reinit(linMomentum, 0);

end when;

linMomentum = totalMassF * length;

totalMassF = section * ( fluidDensity + eps) * veloc;

end pipeDynLiqB;

JARA2i.liq.pipeStatLiqB

JARA2i.liq.pipeStatLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | length | Pipe length [L] | |

| Real | section | Pipe cross-section [L2] | |

| Real | wettedArea | Wetted pipe surface [L2] | |

| Real | heigthI | 0 | Heigth of the input control plane [L] |

| Real | heigthO | 0 | Heigth of the input control plane [L] |

| Real | density[nComp] | Density of the components [M.L-3] | |

| Real | g | 9.8 | Gravitational acceleration [L.t-2] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

| cutReceiver | setPointSignal |

model pipeStatLiqB "Steady-state balance of linear momentum"

extends convecLiqFlowB;

Real valveOpeningSP "Setpoint of the valve opening";

cutsB.cutReceiver setPointSignal( dim=1, signal={valveOpeningSP});

parameter Real length( unit="L") "Pipe length";

parameter Real section( unit="L2") "Pipe cross-section";

parameter Real wettedArea( unit="L2") "Wetted pipe surface";

parameter Real heigthI( unit="L") = 0

"Heigth of the input control plane";

parameter Real heigthO( unit="L") = 0

"Heigth of the input control plane";

parameter Real density[ nComp]( unit="M.L-3") "Density of the components";

parameter Real g( unit="L.t-2") = 9.8

"Gravitational acceleration";

protected

Real veloc( unit="L.t-1", start=0) "Flow velocity";

Real absTotalMassF( unit="M.t-1")

"Absolute value of the total mass flow";

Real pressForce( unit="M.L.t-2")

"Force due to the pressure difference";

Real gravForce( unit="M.L.t-2") "Gravitational force";

Real fluidDensity( unit="M.L-3") "Fluid density";

Real fanning( unit="") "Fanning adimensional factor";

Real parcFluidV[ nComp]( unit="L3") "Volume of each component";

Real massFullPipe( unit="M") "Mass inside the full pipe";

Real massLiqPipe( unit="M") "Liquid mass inside the pipe";

Real totalVolume( unit="L3") "Total volume";

Real totalMassI( unit="M") "Total mass at connector inMass";

Real totalMassO( unit="M") "Total mass at connector outMass";

Real valveOpening( unit="") "Bounded valve opening";

Boolean isPosit( start = true) "Flow direction";

equation

// Density of the liquid mixture

for i in 1:nComp loop

parcFluidV[i] * density[i] = if isPosit then inMass.massL[i] else outMass.massL[i];

end for;

// Total volume

totalVolume = sum(parcFluidV[i] for i in 1:nComp);

// Total mass

totalMassI = sum(inMass.massL[i] for i in 1:nComp);

totalMassO = sum(outMass.massL[i] for i in 1:nComp);

fluidDensity = if isPosit then

totalMassI / ( totalVolume + eps) else

totalMassO / ( totalVolume + eps);

// Force due to the pressure difference

pressForce = section * ( inMass.pressL - outMass.pressL);

// Gravitational force

gravForce = massLiqPipe * g * ( heigthI - heigthO) / length;

massFullPipe = fluidDensity * section * length;

massLiqPipe = if heigthI > heigthO and totalMassI > massFullPipe or

heigthO > heigthI and totalMassO > massFullPipe then

massFullPipe else

if heigthI > heigthO then

totalMassI else

totalMassO;

// Flow direction

new(isPosit) = not pressForce + gravForce < 0;

// Control signal bounding

valveOpening = if valveOpeningSP > 1 then

1 else

if valveOpeningSP < 0 then

0 else

valveOpeningSP;

// Linear momentum balance

absTotalMassF = valveOpening * section * sqrt(2 * fluidDensity / ( wettedArea * fanning + eps)) *

sqrt( abs( pressForce + gravForce));

totalMassF * ( abs( pressForce + gravForce) + eps) = ( pressForce + gravForce) * ( absTotalMassF + eps);

// Fluid velocity

totalMassF = section * ( fluidDensity + eps) * veloc + residue( veloc);

end pipeStatLiqB;

JARA2i.liq.pressEqLiqB

JARA2i.liq.pressEqLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | Kprop | 10 | Slope of the pressure difference vs the total flow [L.t] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

model pressEqLiqB "Liquid flowing through a pipe"

extends convecLiqFlowB;

parameter Real Kprop( unit="L.t") = 10

"Slope of the pressure difference vs the total flow";

protected

Real pressDif( unit="M.L-1.t-2") "Difference of pressures";

Real relatError "Relative error made assuming that the pressures are equal";

equation

// Difference of pressures

// It has been arbitrary defined that the flow is proportional to the pressure gradient.

pressDif = inMass.pressL - outMass.pressL;

// Tne total flow is proportional to the pressure difference

totalMassF = Kprop * pressDif;

// Relative error of assuming that the two pressures are equal

relatError = abs(pressDif) / ( 0.5 * ( inMass.pressL + outMass.pressL + eps));

end pressEqLiqB;

JARA2i.liq.pumpLiqB

JARA2i.liq.pumpLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

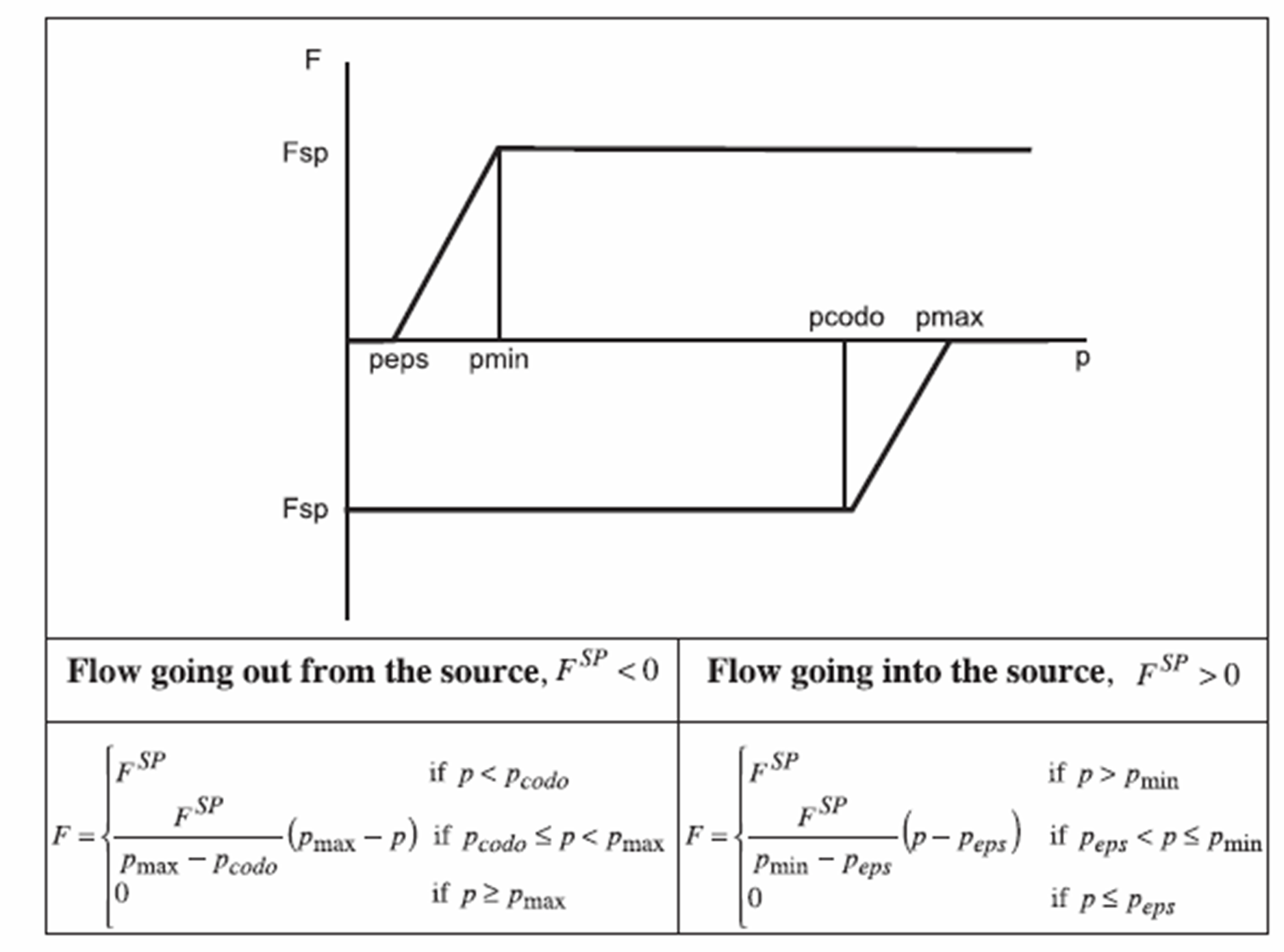

partial model pumpLiqB "Partial model: liquid pump"

extends convecLiqFlowB;

Real totalMassFSP( unit="M.t-1") "Setpoint of the total mass flow";

// pmax > pcodo , pmin > peps

parameter Real pmax( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real pmin( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real pcodo( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real peps( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

protected

Real pressTo( unit="M.L-1.t-2") "Load pressure";

Real pressFrom( unit="M.L-1.t-2") "Source pressure";

Real coefPressTo "Dummy variable";

Real coefPressFrom "Dummy variable";

equation

// Load pressure

pressTo = if totalMassFSP > 0 then outMass.pressL else inMass.pressL;

// Load pressure

pressFrom = if totalMassFSP > 0 then inMass.pressL else outMass.pressL;

// Constitutive relation of the pump

coefPressTo = if pressTo < pcodo then

1 else

if pressTo < pmax then

(pmax-pressTo) / (pmax-pcodo) else

0;

coefPressFrom = if pressFrom > pmin then

1 else

if pressFrom > peps then

( pressFrom - peps) / ( pmin - peps) else

0;

totalMassF = coefPressTo * coefPressFrom * totalMassFSP;

end pumpLiqB;

JARA2i.liq.pumpMassLiqB

JARA2i.liq.pumpMassLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

| cutReceiver | setPointSignal | Set.point signal |

model pumpMassLiqB "Liquid pump. Setpoint: mass flow"

extends pumpLiqB;

cutsB.cutReceiver setPointSignal( dim=1, signal={totalMassFSP})

"Set.point signal";

end pumpMassLiqB;

JARA2i.liq.pumpMolLiqB

JARA2i.liq.pumpMolLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| molecWeigth[nComp] | Molecular weight of the components. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | molecWeigthInitial[nComp] | Molecular weigth of the components [M.mol-1] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

| cutReceiver | setPointSignal | Set.point signal |

model pumpMolLiqB "Liquid pump. Setpoint: molar flow"

extends pumpLiqB;

Real totalMolFSP( unit="mol.t-1") "Setpoint of the total molar flow";

parameter Real molecWeigthInitial[nComp]( unit="M.mol-1")

"Molecular weigth of the components";

cutsB.cutReceiver setPointSignal( dim=1, signal={totalMolFSP})

"Set.point signal";

// Interactive variables

Real molecWeigth[nComp]( unit="M.mol-1",start=molecWeigthInitial)

"Molecular weigth of the components";

protected

Real molI[ nComp]( unit="mol") "Mol number of each component";

Real molO[ nComp]( unit="mol") "Mol number of each component";

Real totalMolI( unit="mol");

Real totalMolO( unit="mol");

Real totalMassI( unit="M");

Real totalMassO( unit="M");

equation

// Ejs

if Ejs then

for i in 1:nComp loop

der(molecWeigth[i]) = 0;

end for;

end if;

// Sysquake

if Sysquake then

molecWeigth = molecWeigthInitial;

end if;

for i in 1:nComp loop

inMass.massL[i] = molecWeigth[i] * molI[i];

outMass.massL[i] = molecWeigth[i] * molO[i];

end for;

totalMolI = sum(molI[i] for i in 1:nComp);

totalMolO = sum(molO[i] for i in 1:nComp);

totalMassI = sum(inMass.massL[i] for i in 1:nComp);

totalMassO = sum(outMass.massL[i] for i in 1:nComp);

totalMassFSP = if totalMolFSP > 0 then

totalMassI * totalMolFSP / (totalMolI + eps) else

totalMassO * totalMolFSP / (totalMolO + eps);

end pumpMolLiqB;

JARA2i.liq.pumpVolLiqB

JARA2i.liq.pumpVolLiqB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| density[nComp] | Density of the components. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | eps | 1.E-6 | Small constant to avoid by-zero division |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | densityInitial[nComp] | Density of the components [M.L-3] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow connector - R |

| cutLiquidR | outMass | Liquid flow connector - R |

| cutHeatFC | inHeat | Heat flow connector -C |

| cutReceiver | setPointSignal | Set.point signal |

model pumpVolLiqB "Liquid pump. Setpoint: volumetric flow"

extends pumpLiqB;

Real totalVolFSP( unit="L3.t-1") "Setpoint of the total volumetric flow";

parameter Real densityInitial[nComp]( unit="M.L-3")

"Density of the components";

cutsB.cutReceiver setPointSignal( dim=1, signal={totalVolFSP})

"Set.point signal";

// Interactive variables

Real density[nComp]( unit="M.L-3",start=densityInitial)

"Density of the components";

protected

Real mixDensity( unit="M.L-3") "Density of the mixture";

Real massFract[ nComp] "Mass fraction of the flow";

equation

// Ejs

if Ejs then

for i in 1:nComp loop

der(density[i]) = 0;

end for;

end if;

// Sysquake

if Sysquake then

density = densityInitial;

end if;

totalMassFSP = totalVolFSP * mixDensity;

mixDensity = 1 / ( sum( massFract[i] / density[i] for i in 1:nComp));

massFract = if totalVolFSP > 0 then

inMass.massL / ( sum(inMass.massL[i] for i in 1:nComp) + eps) else

outMass.massL / ( sum(outMass.massL[i] for i in 1:nComp) + eps);

end pumpVolLiqB;

JARA2i.liq.sourceLiqFB

JARA2i.liq.sourceLiqFB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | eps | 1.E-8 | Small constant to avoid by-zero division |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Connector for the liquid flow |

partial model sourceLiqFB "Partial model: liquid source"

extends interf.liqFlow1I;

// Interactivity

outer parameter Boolean Ejs = false

"Global parameter - Runtime interactivity";

outer parameter Boolean Sysquake = false

"Global parameter - Batch interactivity";

Real massFractSP[ nComp]( unit="") "Setpoint of the mass fraction";

Real tempFSP( unit="T") "Setpoint of the flow temperature";

Real totalMassFSP( unit="M*t**-1") "Setpoint of the total mass flow";

parameter Real CpCoefMInitial[nComp,7] "Coefficients of the specific (per mass) heat capacity

CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6";

parameter Real massEnthalpyRefInitial[nComp]( unit="L2.t-2") = zeros(nComp)

"Specific (per mass) enthalpy at the reference temperature";

parameter Real tempRefInitial( unit="T") = 298

"Reference temperature for the enthalpy";

// pmax > pcodo , pmin > peps

parameter Real pmax( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real pmin( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real pcodo( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real peps( unit="M.L-1.t-2")

"Parameter of the pump constitutive relation";

parameter Real eps = 1.E-8 "Small constant to avoid by-zero division";

Real totalMassF( unit="M*t**-1") "Total mass flow";

Real tempF( unit="T") "Flow temperature";

// Interactive variables

Real CpCoefM[nComp,7]( start=CpCoefMInitial) "Coefficients of the specific (per mass) heat capacity

CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6";

Real massEnthalpyRef[nComp]( unit="L2.t-2",start=massEnthalpyRefInitial)

"Specific (per mass) enthalpy at the reference temperature";

Real tempRef( unit="T",start=tempRefInitial)

"Reference temperature for the enthalpy";

protected

Boolean flowIsPosit( start = true) "Flow direction";

Real totalMass( unit="M") "Total mass";

Real aux[ nComp];

equation

// Ejs

if Ejs then

for i in 1:nComp loop

for j in 1:7 loop

der(CpCoefM[i,j]) = 0;

end for;

end for;

for i in 1:nComp loop

der(massEnthalpyRef[i]) = 0;

end for;

der(tempRef) = 0;

end if;

// Sysquake

if Sysquake then

CpCoefM = CpCoefMInitial;

massEnthalpyRef = massEnthalpyRefInitial;

tempRef = tempRefInitial;

end if;

// Constitutive relation of the source

flowIsPosit = totalMassFSP > 0;

totalMassF = if flowIsPosit and totalMass < 1e-5 then

0 else

if flowIsPosit and inMass.pressL > pmin then

totalMassFSP else

if flowIsPosit and inMass.pressL > peps then

totalMassFSP * ( inMass.pressL - peps) / ( pmin - peps) else

if flowIsPosit then

0 else

if inMass.pressL < pcodo then

totalMassFSP else

if inMass.pressL < pmax then

totalMassFSP * ( pmax - inMass.pressL) / ( pmax - pcodo) else

0;

// Total mass

totalMass = sum(inMass.massL[i] for i in 1:nComp);

// Flow of each component

if nComp > 1 then

for i in 1:(nComp-1) loop

inMass.massLF[i] = if flowIsPosit then

inMass.massL[i] * totalMassF / ( totalMass + eps) else

massFractSP[i] * totalMassF;

end for;

end if;

totalMassF = sum(inMass.massLF[i] for i in 1:nComp);

// Flow temperature

tempF = if flowIsPosit then inMass.tempL else tempFSP;

// Enthalpy flow

for i in 1:nComp loop

aux[i] = CpCoefM[i,1] * ( tempF - tempRef) +

CpCoefM[i,2] * 1/2 * ( tempF^ 2 - tempRef^ 2) +

CpCoefM[i,3] * 1/3 * ( tempF^ 3 - tempRef^ 3) +

CpCoefM[i,4] * 1/4 * ( tempF^ 4 - tempRef^ 4) +

CpCoefM[i,5] * 1/5 * ( tempF^ 5 - tempRef^ 5) +

CpCoefM[i,6] * 1/6 * ( tempF^ 6 - tempRef^ 6) +

CpCoefM[i,7] * 1/7 * ( tempF^ 7 - tempRef^ 7);

end for;

inMass.energyLF = sum(inMass.massLF[i] * ( massEnthalpyRef[i] + aux[i]) for i in 1:nComp);

end sourceLiqFB;

JARA2i.liq.sourceMassLiqFB

JARA2i.liq.sourceMassLiqFB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | eps | 1.E-8 | Small constant to avoid by-zero division |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Connector for the liquid flow |

| cutReceiver | setPointSignal | Set point signals |

model sourceMassLiqFB "Liquid source. Setpoints: total mass, mass fraction and temperature" extends sourceLiqFB; cutsB.cutReceiver setPointSignal( dim=nComp+2) "Set point signals"; equation setPointSignal.signal[1] = totalMassFSP; setPointSignal.signal[2:(nComp+1)] = massFractSP; setPointSignal.signal[nComp+2] = tempFSP; end sourceMassLiqFB;

JARA2i.liq.sourceMolLiqFB

JARA2i.liq.sourceMolLiqFB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | eps | 1.E-8 | Small constant to avoid by-zero division |

| Real | molecWeigth[nComp] | Molecular weigth of the components [M.mol-1] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Connector for the liquid flow |

| cutReceiver | setPointSignal |

model sourceMolLiqFB

"Liquid source. Setpoints: total molar flow, molar fraction and temperature."

extends sourceLiqFB;

Real totalMolFSP( unit="M.t-1")

"Setpoint of the total molar flow";

Real molFractSP[ nComp]( unit="") "Setpoint of the molar fraction";

parameter Real molecWeigth[ nComp]( unit="M.mol-1")

"Molecular weigth of the components";

cutsB.cutReceiver setPointSignal( dim=nComp+2);

protected

Real auxCal "Auxiliary variable";

equation

setPointSignal.signal[1] = totalMolFSP;

setPointSignal.signal[2:(nComp+1)] = molFractSP;

setPointSignal.signal[nComp+2] = tempFSP;

auxCal = sum(molecWeigth[i] * molFractSP[i] for i in 1:nComp);

for i in 1:nComp loop

massFractSP[i] = molecWeigth[i] * molFractSP[i] / auxCal;

end for;

totalMassFSP = auxCal * totalMolFSP;

end sourceMolLiqFB;

JARA2i.liq.sourcePressLiqB

JARA2i.liq.sourcePressLiqB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components of the liquid mixture |

| Type | Name | Description |

|---|---|---|

| cutLiquidC | inMass | Connector for the liquid flow |

model sourcePressLiqB "Pressure source." extends interf.liquid1I; equation end sourcePressLiqB;

JARA2i.liq.sourceVolLiqFB

JARA2i.liq.sourceVolLiqFB

| CpCoefM[nComp,7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6. |

| massEnthalpyRef[nComp] | Specific (per mass) enthalpy at the reference temperature. |

| tempRef | Reference temperature for the enthalpy. |

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Boolean | Ejs | false | Global parameter - Runtime interactivity |

| Boolean | Sysquake | false | Global parameter - Batch interactivity |

| Real | CpCoefMInitial[nComp, 7] | Coefficients of the specific (per mass) heat capacity CpM[i] = CpCoefM[i,1] + CpCoefM[i,2]*T + ... + CpCoefM[i,7]*T**6 | |

| Real | massEnthalpyRefInitial[nComp] | zeros(nComp) | Specific (per mass) enthalpy at the reference temperature [L2.t-2] |

| Real | tempRefInitial | 298 | Reference temperature for the enthalpy [T] |

| Real | pmax | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pmin | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | pcodo | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | peps | Parameter of the pump constitutive relation [M.L-1.t-2] | |

| Real | eps | 1.E-8 | Small constant to avoid by-zero division |

| Real | densityInitial[nComp] | Density of the components [M.L-3] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Connector for the liquid flow |

| cutReceiver | setPointSignal | Setpoint signals |

model sourceVolLiqFB

"Liquid source. Setpoints: total volumetric flow, volume fraction and temperature."

extends sourceLiqFB;

Real volFractSP[ nComp]( unit="") "Setpoint of the volume fraction";

Real totalVolFSP( unit="L3.t-1")

"Setpoint of the total volumetric flow";

parameter Real densityInitial[nComp]( unit="M.L-3")

"Density of the components";

cutsB.cutReceiver setPointSignal( dim=nComp+2) "Setpoint signals";

// Interactive variables

Real density[nComp]( unit="M.L-3",start=densityInitial)

"Density of the components";

protected

Real mixDensity( unit="M.L-3") "Density of the mixture";

Real auxCal "Auxiliary variable";

equation

// Ejs

if Ejs then

for i in 1:nComp loop

der(density[i]) = 0;

end for;

end if;

// Sysquake

if Sysquake then

density = densityInitial;

end if;

setPointSignal.signal[1] = totalVolFSP;

setPointSignal.signal[2:(nComp+1)] = volFractSP;

setPointSignal.signal[nComp+2] = tempFSP;

auxCal = sum(volFractSP[i] * density[i] for i in 1:nComp);

for i in 1:nComp loop

massFractSP[i] = volFractSP[i] * density[i] / auxCal;

end for;

totalMassFSP = totalVolFSP * mixDensity;

mixDensity = 1 / ( sum(massFractSP[i] / density[i] for i in 1:nComp));

end sourceVolLiqFB;

JARA2i.liq.vesselLiqB

JARA2i.liq.vesselLiqB

| vesselVolume | Vessel Volume. |

| Type | Name | Default | Description |

|---|---|---|---|

| Boolean | Ejs | false | Run-time interactivity |

| Boolean | Sysquake | false | Batch interactivity |

| Real | vesselVolumeInitial | Vessel volume. Initial value [L3] |

| Type | Name | Description |

|---|---|---|

| cutVolConstrVessel | constraintV | Volume constraint - Vessel. |

model vesselLiqB "Vessel with a constant volume."

extends interf.vesselI;

// Interactivity

outer parameter Boolean Ejs = false "Run-time interactivity";

outer parameter Boolean Sysquake = false "Batch interactivity";

parameter Real vesselVolumeInitial( unit="L3")

"Vessel volume. Initial value";

Real vesselVolume( unit="L3", start=vesselVolumeInitial)

"Vessel volume";

equation

// Ejs

if Ejs then

der(vesselVolume) = 0;

end if;

// Sysquake

if Sysquake then

vesselVolume = vesselVolumeInitial;

end if;

// The vessel volume is constant

// constraintV.vesselV = vesselVolume;

constraintV.vcE[1] = vesselVolume;

end vesselLiqB;