| Name | Description |

|---|---|

| Boiling model | |

| Condensation model | |

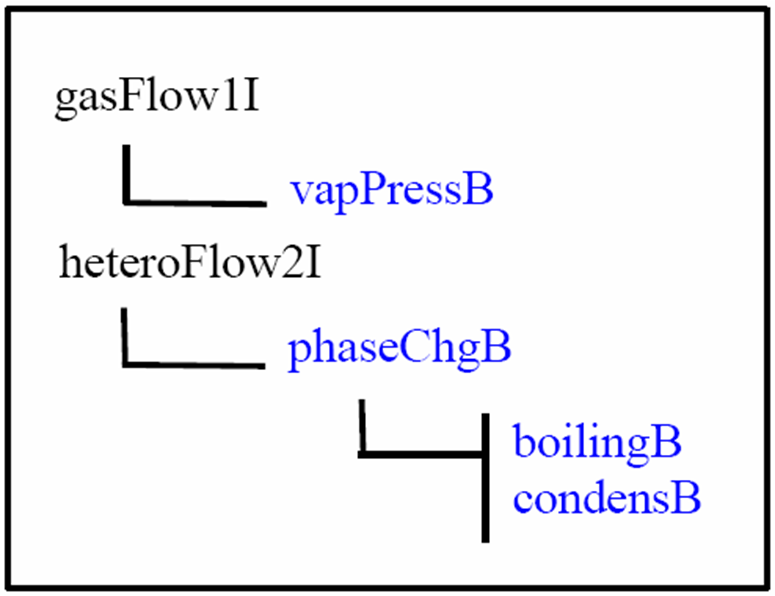

| Partial model - Model describing a phase change | |

| Boundary condition for the partial pressure of one of the component of a gas mixture |

JARA2i.phase.boilingB

JARA2i.phase.boilingB

.

.  .

.

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | massEnthalpyLRef[nComp] | zeros(nComp) | Specific (per mass) enthalpy of the liquid components at the reference temperature [L2.t-2] |

| Real | molEnthalpyGRef[nComp] | zeros(nComp) | Specific (per mol) enthalpy of the gas components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for the enthalpy [T] |

| Real | CpCoefML[nComp, 7] | Liquid components: coefficients of the specific (per mass) heat capacity Cp unit: L2.t-2.T-1 Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | CpCoefNG[nComp, 7] | Vapor components: coefficients of the specific (per mol) heat capacity at constant pressure. Cp unit: M.L2.t-2.T-1.mol-1 Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | molecWeigth[nComp] | Molecular weigth of the components [M.mol-1] | |

| Real | eps | 1E-8 | Small constant to avoid by-zero division |

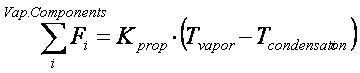

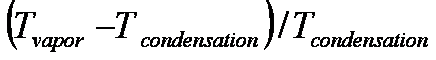

| Real | Kprop | [M.t-1.T-1] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow - Connector R. Connector for the liquid flow. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

model boilingB "Boiling model"

extends phaseChgB;

parameter Real Kprop( unit="M.t-1.T-1");

Boolean boiling( start = false, fixed=true) "True: the liquid is boiling

False: the liquid is not boiling";

Boolean noBoiling( start = true, fixed=true) "True : the liquid is not boiling

False: the liquid is boiling";

Real tempBoiling( unit="K") "Temperature of the boiling point";

Real compVaporBoil[ nComp] "Composition (mass fraction of each component)

of the vapor flowing from the liquid, due to the boiling";

Real error( unit="T")

"Difference between the liquid temperature and its boiling temperature";

equation

// Boiling condition

boiling = pre(noBoiling) and not inMass.tempL < tempBoiling or

pre(boiling) and not ( totalMassF < - eps or not ( sum(inMass.massL[i] for i in 1:nComp) > eps));

noBoiling = pre(boiling) and ( totalMassF < - eps or not ( sum(inMass.massL[i] for i in 1:nComp) > eps)) or

pre(noBoiling) and not ( not inMass.tempL < tempBoiling);

// Difference between the liquid temperature and its boiling temperature

error = inMass.tempL - tempBoiling;

// Mass flow due to the boiling

0 = if boiling then totalMassF - Kprop * error else inMass.massLF[1];

if nComp > 1 then

for i in 1:(nComp-1) loop

0 = if boiling then

compVaporBoil[i] - inMass.massLF[i] / ( totalMassF + eps) else

inMass.massLF[i+1];

end for;

end if;

// Direction of the flow

flowIsPosit = true;

end boilingB;

JARA2i.phase.condensB

JARA2i.phase.condensB

.

.  .

.

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | massEnthalpyLRef[nComp] | zeros(nComp) | Specific (per mass) enthalpy of the liquid components at the reference temperature [L2.t-2] |

| Real | molEnthalpyGRef[nComp] | zeros(nComp) | Specific (per mol) enthalpy of the gas components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for the enthalpy [T] |

| Real | CpCoefML[nComp, 7] | Liquid components: coefficients of the specific (per mass) heat capacity Cp unit: L2.t-2.T-1 Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | CpCoefNG[nComp, 7] | Vapor components: coefficients of the specific (per mol) heat capacity at constant pressure. Cp unit: M.L2.t-2.T-1.mol-1 Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | molecWeigth[nComp] | Molecular weigth of the components [M.mol-1] | |

| Real | eps | 1E-8 | Small constant to avoid by-zero division |

| Real | Kprop | [mol.t-1.T-1] |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow - Connector R. Connector for the liquid flow. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

model condensB "Condensation model"

extends phaseChgB;

parameter Real Kprop( unit="mol.t-1.T-1");

protected

Boolean condens( start=false, fixed=true) "True: the liquid is condensing

False: the liquid is not condensing";

Boolean noCondens( start=true, fixed=true) "True : the liquid is not condensing

False: the liquid is condensing";

Real tempCondens( unit="T") "Temperature of the dew point";

Real compLiqCond[ nComp] "Composition (mass fraction of each component)

of the liquid flowing from the vapor, due to the condensation";

Real error( unit="T")

"Difference between the liquid temperature and its dew temperature";

equation

// Condensation

condens = pre(noCondens) and not outMol.tempG > tempCondens or

pre(condens) and not ( totalMolF > eps or not ( sum(outMol.molG[i] for i in 1:nComp) > eps));

noCondens = pre(condens) and ( totalMolF > eps or not ( sum(outMol.molG[i] for i in 1:nComp) > eps)) or

pre(noCondens) and not ( not outMol.tempG > tempCondens);

// Difference between the liquid temperature and its dew temperature

error = outMol.tempG - tempCondens;

// Mass flow due to the condensation

0 = if condens then totalMolF - Kprop * error else outMol.molGF[1];

if nComp > 1 then

for i in 1:(nComp-1) loop

0 = if condens then

compLiqCond[i] - outMol.molGF[i] / ( totalMolF + eps) else

outMol.molGF[i+1];

end for;

end if;

// Flow direction

flowIsPosit = false;

end condensB;

JARA2i.phase.phaseChgB

JARA2i.phase.phaseChgB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | nComp | 1 | Number of components |

| Real | massEnthalpyLRef[nComp] | zeros(nComp) | Specific (per mass) enthalpy of the liquid components at the reference temperature [L2.t-2] |

| Real | molEnthalpyGRef[nComp] | zeros(nComp) | Specific (per mol) enthalpy of the gas components at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for the enthalpy [T] |

| Real | CpCoefML[nComp, 7] | Liquid components: coefficients of the specific (per mass) heat capacity Cp unit: L2.t-2.T-1 Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | CpCoefNG[nComp, 7] | Vapor components: coefficients of the specific (per mol) heat capacity at constant pressure. Cp unit: M.L2.t-2.T-1.mol-1 Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6 | |

| Real | molecWeigth[nComp] | Molecular weigth of the components [M.mol-1] | |

| Real | eps | 1E-8 | Small constant to avoid by-zero division |

| Type | Name | Description |

|---|---|---|

| cutLiquidR | inMass | Liquid flow - Connector R. Connector for the liquid flow. |

| cutGasR | outMol | Gas flow - Connector Resistive. |

partial model phaseChgB

"Partial model - Model describing a phase change"

extends JARA2i.interf.heteroFlow2I;

parameter Real massEnthalpyLRef[nComp]( unit="L2.t-2") = zeros(nComp)

"Specific (per mass) enthalpy of the liquid components at the reference temperature";

parameter Real molEnthalpyGRef[nComp]( unit="M.L2.t-2.mol-1") = zeros(nComp)

"Specific (per mol) enthalpy of the gas components at the reference temperature";

parameter Real tempRef( unit="T") = 298

"Reference temperature for the enthalpy";

parameter Real CpCoefML[nComp,7] "Liquid components: coefficients of the specific (per mass) heat capacity

Cp unit: L2.t-2.T-1

Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6";

parameter Real CpCoefNG[nComp,7] "Vapor components: coefficients of the specific (per mol) heat capacity

at constant pressure. Cp unit: M.L2.t-2.T-1.mol-1

Cp[i] = CpCoef[i,1] + CpCoef[i,2]*T + ... + CpCoef[i,7]*T**6";

parameter Real molecWeigth[nComp]( unit="M.mol-1")

"Molecular weigth of the components";

parameter Real eps = 1E-8 "Small constant to avoid by-zero division";

Real totalMassF( unit="M.t-1")

"Total mass-flow due to the phase change";

Real totalMolF( unit="mol.t-1")

"Total molar-flow due to the phase change";

Real tempF( unit="T")

"Temperature of the flow between the phases";

Real massHeatPhaseChg( unit="L2.t-2")

"Change-of-phase heat per mass unit";

Real massEnthalpyL[ nComp]( unit="L2.t-2")

"Specific (per mass) enthalpy of the liquid components";

Real molEnthalpyL[ nComp]( unit="M.L2.t-2.mol-1")

"Molar enthalpy of the liquid components";

Real molEnthalpyG[ nComp]( unit="M.L2.t-2.mol-1")

"Molar enthalpy of the vapor components";

Real massEnthalpyG[ nComp]( unit="L2.t-2")

"Specific (per mass) enthalpy of the vapor components";

Boolean flowIsPosit "True: flow from liquid to vapor phase

False: flow from vapor to liquid phase";

equation

// Total mass flow due to the phase change. Positive: flow from liquid to vapor phase.

totalMassF = sum(inMass.massLF[i] for i in 1:nComp);

totalMolF = -sum(outMol.molGF[i] for i in 1:nComp);

for i in 1:nComp loop

molecWeigth[i] * outMol.molGF[i] + inMass.massLF[i] = 0;

end for;

// Relationship between the molar enthalpy and the specific (per mass) enthalpy

for i in 1:nComp loop

molecWeigth[i] * molEnthalpyG[i] = massEnthalpyG[i];

molecWeigth[i] * molEnthalpyL[i] = massEnthalpyL[i];

end for;

// Temperature of the change-of-phase flow

tempF = if flowIsPosit then inMass.tempL else outMol.tempG;

// Enthalpy flow associated to the change-of-phase mass flow. Positive: flow from liquid to vapor

inMass.energyLF = if flowIsPosit then

-sum(outMol.molGF[i] * molEnthalpyG[i] for i in 1:nComp) else

sum(inMass.massLF[i] * massEnthalpyL[i] for i in 1:nComp);

outMol.energyGF + inMass.energyLF = 0;

// Specific (per mass) enthalpy of the liquid components

for i in 1:nComp loop

massEnthalpyL[i] = massEnthalpyLRef[i] +

CpCoefML[i,1] * ( tempF - tempRef) +

CpCoefML[i,2] * 1/2 * ( tempF^ 2 - tempRef^ 2) +

CpCoefML[i,3] * 1/3 * ( tempF^ 3 - tempRef^ 3) +

CpCoefML[i,4] * 1/4 * ( tempF^ 4 - tempRef^ 4) +

CpCoefML[i,5] * 1/5 * ( tempF^ 5 - tempRef^ 5) +

CpCoefML[i,6] * 1/6 * ( tempF^ 6 - tempRef^ 6) +

CpCoefML[i,7] * 1/7 * ( tempF^ 7 - tempRef^ 7);

end for;

// Molar enthalpy of the liquid components

for i in 1:nComp loop

molEnthalpyG[i] = molEnthalpyGRef[i] +

CpCoefNG[i,1] * ( tempF - tempRef) +

CpCoefNG[i,2] * 1/2 * ( tempF^ 2 - tempRef^ 2) +

CpCoefNG[i,3] * 1/3 * ( tempF^ 3 - tempRef^ 3) +

CpCoefNG[i,4] * 1/4 * ( tempF^ 4 - tempRef^ 4) +

CpCoefNG[i,5] * 1/5 * ( tempF^ 5 - tempRef^ 5) +

CpCoefNG[i,6] * 1/6 * ( tempF^ 6 - tempRef^ 6) +

CpCoefNG[i,7] * 1/7 * ( tempF^ 7 - tempRef^ 7);

end for;

// Change-of-phase heat per mass unit

// Positive: boiling of a mass unit of liquid mixture

// Negative: condensation of a mass unit of the vapor mixture

massHeatPhaseChg = ( -sum(outMol.molGF[i] * molEnthalpyG[i] for i in 1:nComp) -

sum(inMass.massLF[i] * massEnthalpyL[i] for i in 1:nComp)) / ( totalMassF + eps);

end phaseChgB;

JARA2i.phase.vapPressB

JARA2i.phase.vapPressB

| Type | Name | Default | Description |

|---|---|---|---|

| Integer | evapComp | Number of the component whose vapor pressure is set | |

| Integer | nComp | 1 | Number of components |

| Real | molEnthalpyRef | 0 | Molar enthalpy of the component at the reference temperature [M.L2.t-2.mol-1] |

| Real | tempRef | 298 | Reference temperature for the enthalpy [T] |

| Real | CpCoefN[1, 7] | Coefficients of the molar heat capacity at constant pressure, of the evapComp component Cp = CpCoefN(1,1) + CpCoefN(1,2)*T + ... | |

| Real | Kprop | 1E4 | Coefficient relating the molar flow of the evapComp component and the pressure difference [mol.L.t.M-1] |

| Real | eps | 1E-4 | Small constant to avoid by-zero division |

| Type | Name | Description |

|---|---|---|

| cutGasR | inMol | Gas flow - Connector Resistive |

| cutReceiver | setPointSignal | Setpoint signals [vaporPressSP, tempEvapSP] |

model vapPressB

"Boundary condition for the partial pressure of one of the component of a gas mixture"

parameter Integer evapComp

"Number of the component whose vapor pressure is set";

extends JARA2i.interf.gasFlow1I;

cutsB.cutReceiver setPointSignal( dim=2, signal={vaporPressSP,tempEvapSP})

"Setpoint signals [vaporPressSP, tempEvapSP]";

Real vaporPressSP( unit="M.L-1.t-2")

"Vapor-pressure setpoint for the evapComp component";

Real tempEvapSP( unit="T")

"Temperature of the component flowing into the control volume";

parameter Real molEnthalpyRef( unit="M.L2.t-2.mol-1") = 0

"Molar enthalpy of the component at the reference temperature";

parameter Real tempRef( unit="T") = 298

"Reference temperature for the enthalpy";

parameter Real CpCoefN[ 1,7] "Coefficients of the molar heat capacity at constant pressure,

of the evapComp component

Cp = CpCoefN(1,1) + CpCoefN(1,2)*T + ...";

parameter Real Kprop( unit="mol.L.t.M-1") = 1E4

"Coefficient relating the molar flow of the evapComp component and the pressure difference";

parameter Real eps = 1E-4 "Small constant to avoid by-zero division";

protected

Real pressErr( unit="M.L-1.t-2")

"Difference between the parcial-pressure setpoint and its actual value";

Real vaporPress( unit="M.L-1.t-2")

"Partial pressure of the evapComp component";

Real aux[nComp+2] "Dummy variables";

Real dummy1 "Dummy variable";

Real dummy2 "Dummy variable";

Real molEnthalpy( unit="M.L2.t-2.mol-1")

"Molar enthalpy of the evapComp component";

Real tempF( unit="T") "Temperature of the evapComp-component flow";

Boolean flowIsPosit "Direction of the evapComp-component flow";

equation

// Vapor pressure of the evapComp component

vaporPress = inMol.pressG * inMol.molG[evapComp] / ( sum(inMol.molG[i] for i in 1:nComp) + eps);

// Difference between the vapor-pressure setpoint and its actual value

pressErr = vaporPressSP + eps - vaporPress;

// Flow of the evapComp component

inMol.molGF[evapComp] = - Kprop * pressErr;

// The flow of all the other components is zero

aux = { dummy1, inMol.molGF, dummy2};

aux[1:evapComp] = 0;

aux[(evapComp+2):(nComp+2)] = 0;

// Molar enthalpy of the evapComp component

for i in 1:nComp loop

molEnthalpy[i] = molEnthalpyRef[i] +

sum( CpCoefN[i,j] * 1/j * ( tempF^ j - tempRef^ j) for j in 1:7);

end for;

// Enthalpy flow

inMol.energyGF = inMol.molGF[evapComp] * molEnthalpy;

// Flow temperture

flowIsPosit = inMol.molGF[evapComp] / ( abs( inMol.molGF[evapComp]) + eps);

tempF = 0.5 * ( 1 + flowIsPosit) * inMol.tempG - 0.5 * ( flowIsPosit -1) * tempEvapSP;

end vapPressB;